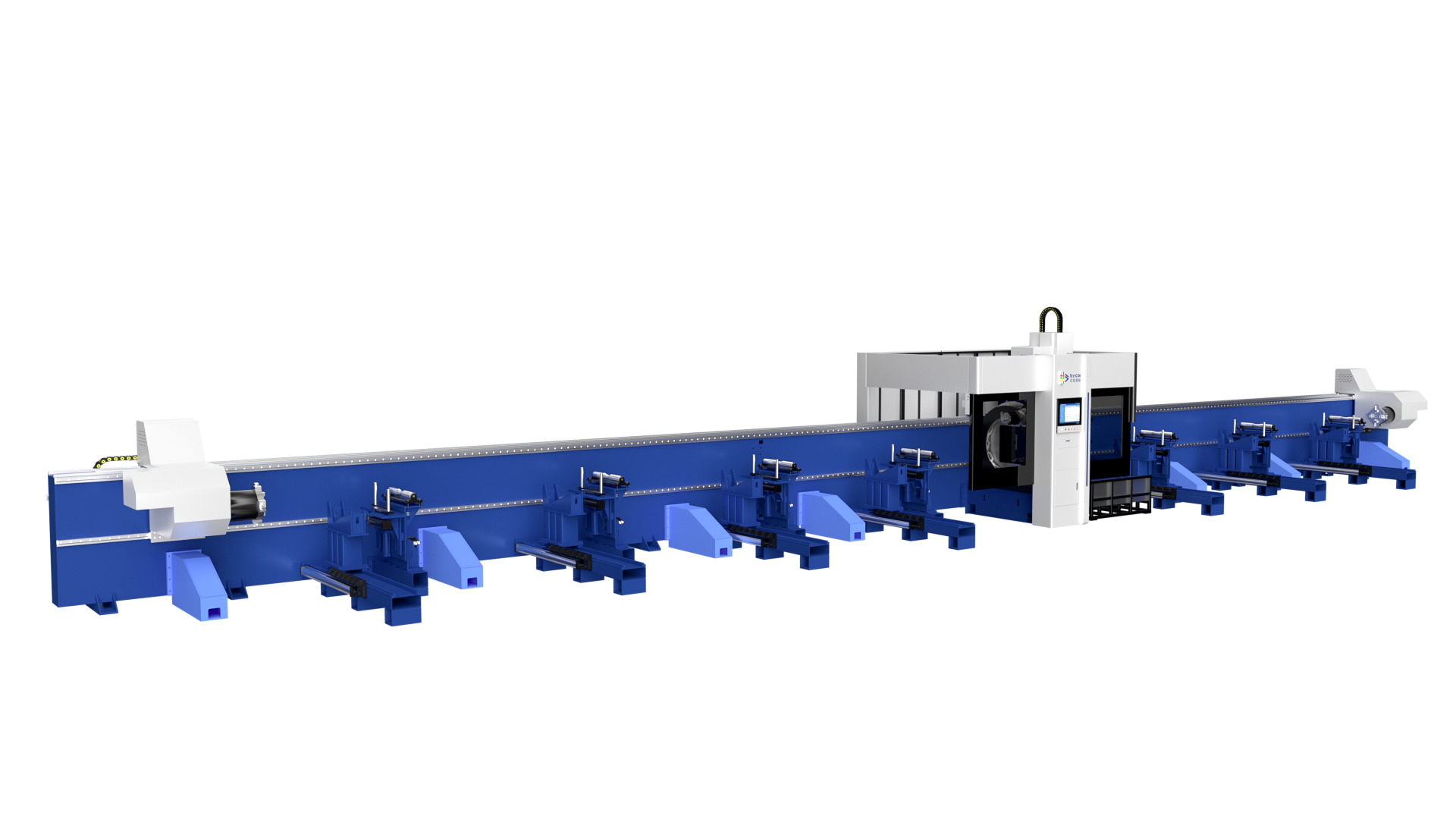

BLT3 系列 3卡盘 管材激光切割机

选择三卡盘管材激光切割机,实现高效无缝加工。其独特三卡盘设计确保精准旋转与稳定支持,大幅提升管材切割效率与精度。

Opt for the 3-Chuck Tube Laser Cutter for seam

机械系统

结构坚固,承重力出色,即使在高速运转时也能保持设备稳固和精准。

床身

高强度结构,保障机身稳定

床身采用高强度结构设计,有效减少振动,提升切割精度和机器寿命。

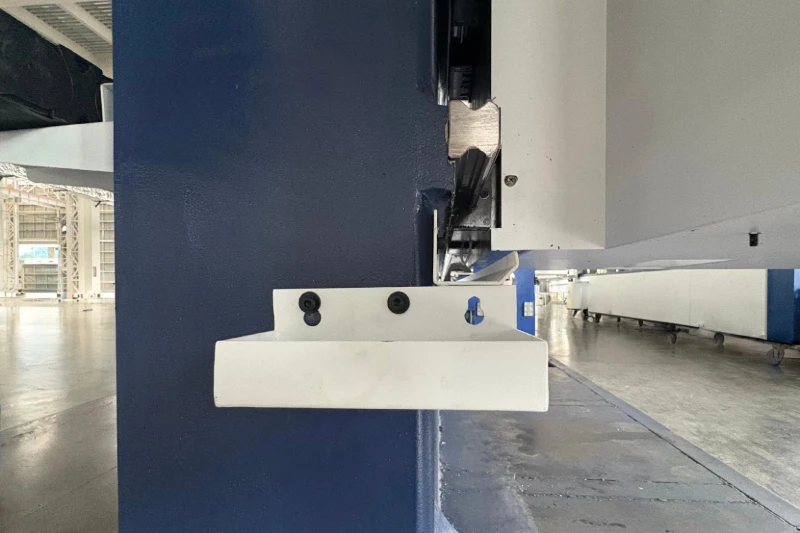

卡盘

精密夹紧,提升加工稳定性

卡盘牢固固定管材,防止旋转偏差,保障切割效果。

卡盘数量

多卡盘设计,适应多规格

多卡盘设计可同时适应不同长度和直径的管材,拓宽加工范围。

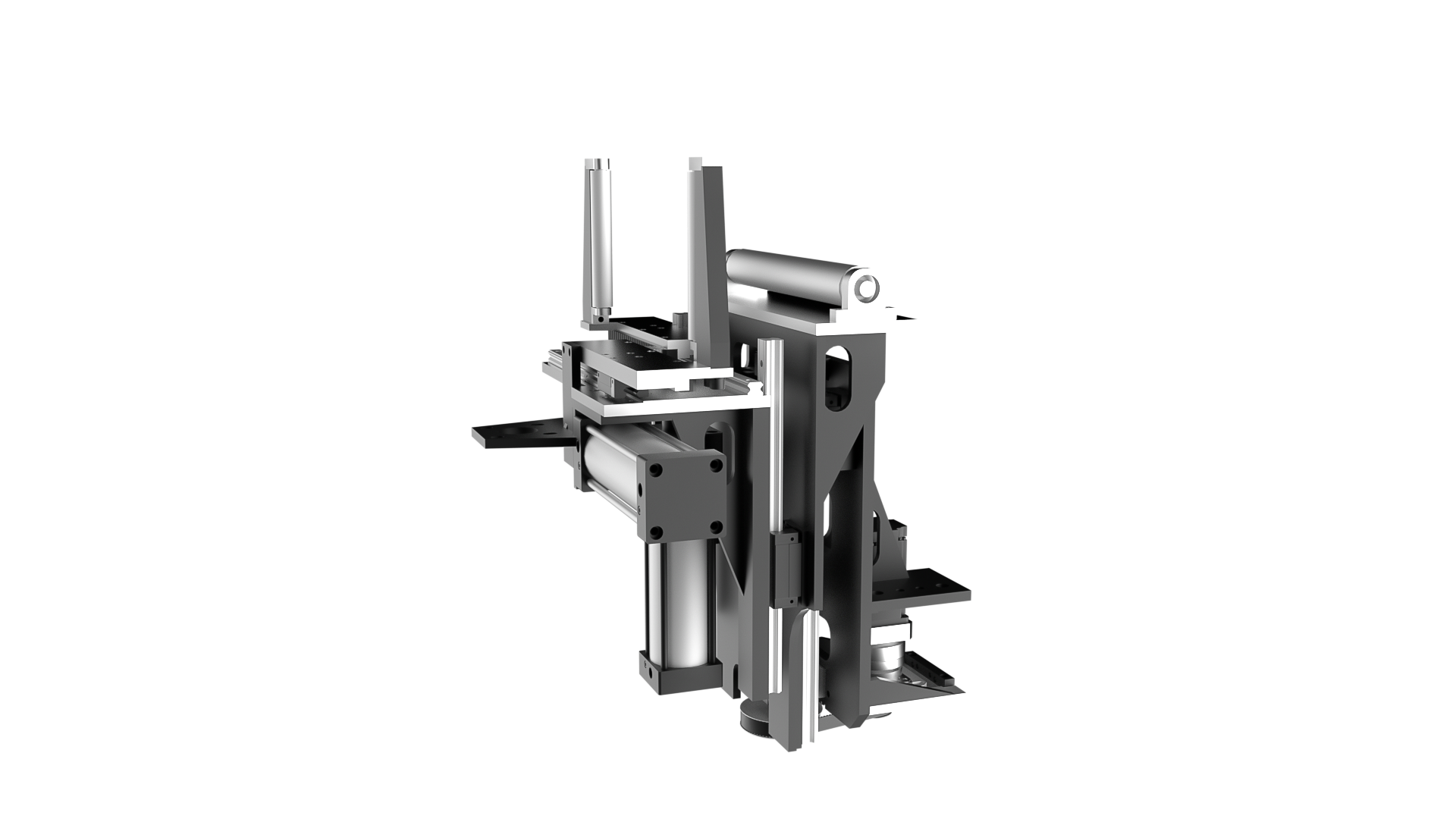

伺服托辊

动态支撑,避免管材下垂

伺服托辊可根据管材位置智能升降,防止长管下垂影响切割精度。

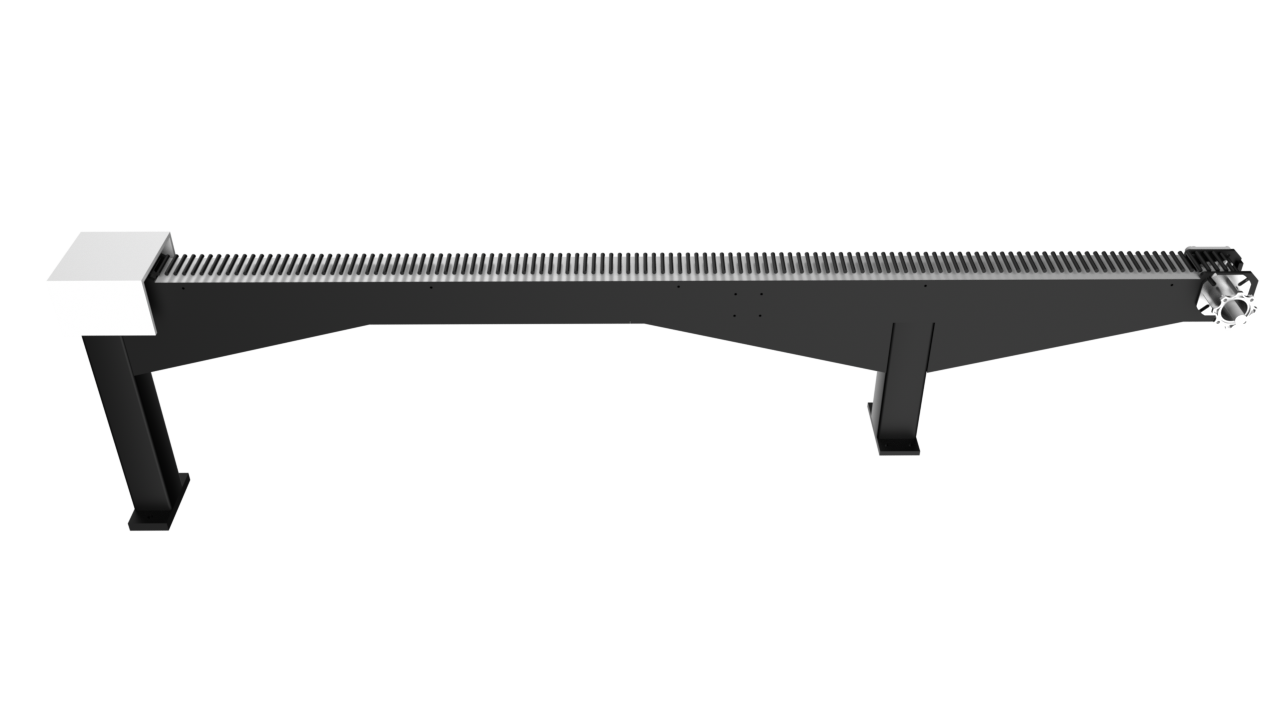

伺服落料架

自动接料,提高生产效率

落料架自动接收成品,减少人工干预,提升整体生产效率。

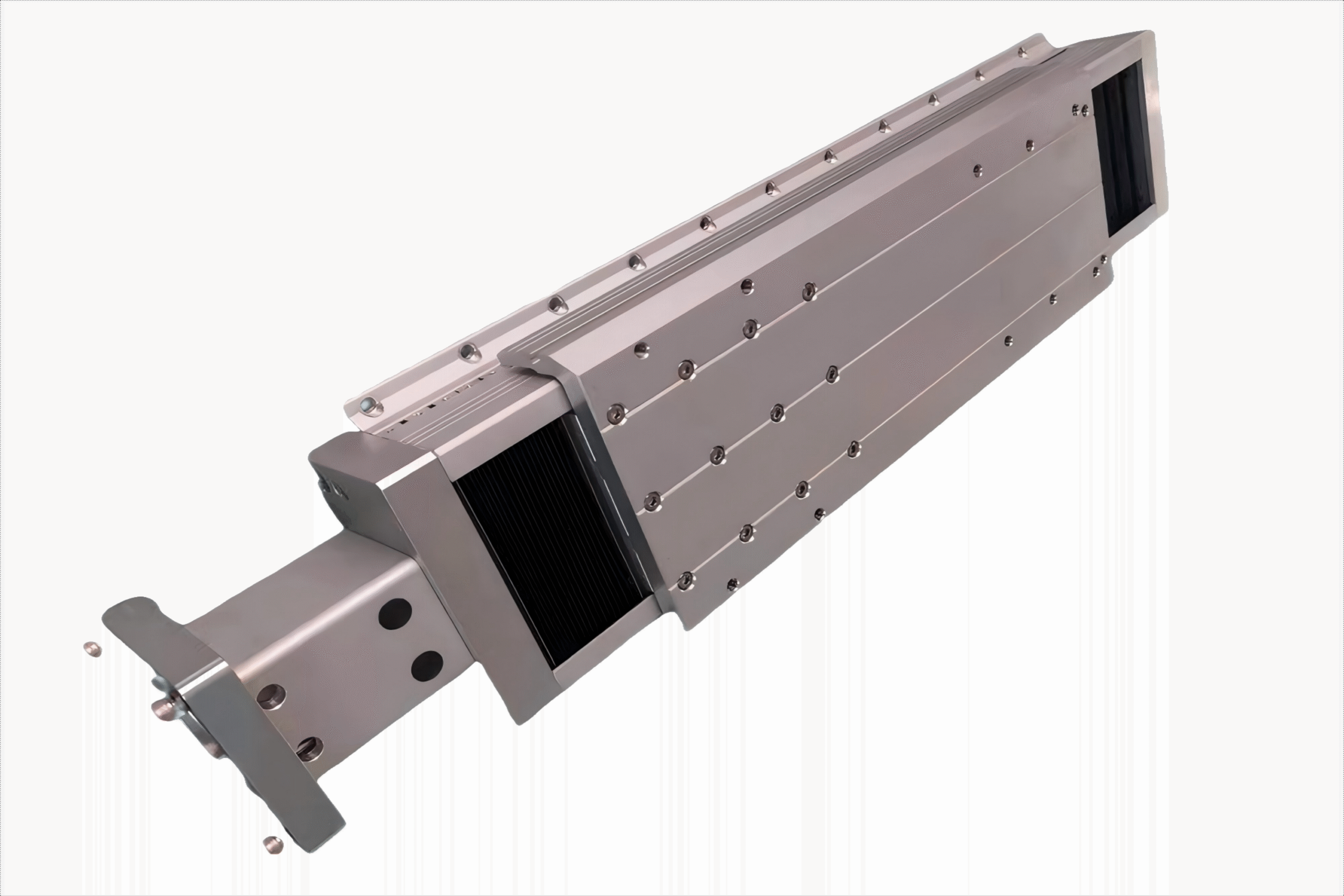

Z轴滑动模组

高精度动态调焦,保障切割品质。

以高刚性结构与精密伺服驱动,确保切割头在高速运动中焦点稳定,无缝适应不同板厚。

运动系统

响应迅速,定位精准,切割过程快速高效且流畅无阻。

伺服电机与驱动

高响应控制,保障切割精度

高响应伺服系统实现精准控制,确保高速运行下切割位置精确无误。

减速机

稳定传动,增强动力输出

减速机提供平稳的动力传递,保证机器运转顺畅且动力充足。

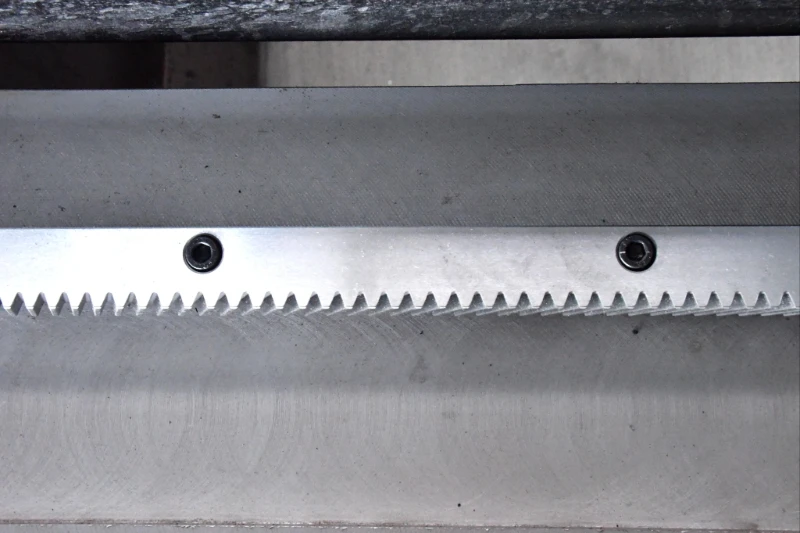

导轨

精密导向,保障平稳运动

高精度导轨系统减少摩擦与偏移,确保运动平稳且延长设备寿命。

齿条

高效传动,提升定位精度

齿条传动结构具备高速响应能力,提升定位精度和加工效率。

拖链

整理线缆,减少磨损风险

拖链有序管理电缆和气管,防止弯折与磨损,保障系统稳定运行。

光学系统

激光输出稳定,切割线条细腻整齐,带来卓越的加工品质。

激光器

稳定光源,实现卓越品质

激光器输出稳定高能光束,实现高速、光洁的切割效果。

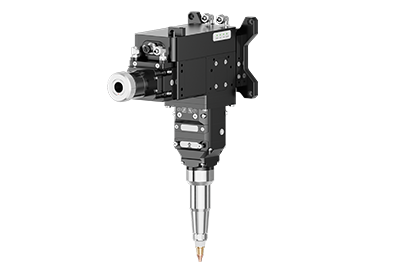

切割头

智能聚焦,适应多种材料

切割头具备智能调焦功能,灵活应对不同材质与厚度的切割需求。

控制系统

操作界面简洁易用,流程顺畅,显著提高生产效率。

切割总线系统

集中控制,提高响应效率

总线系统集成多种控制模块,提升数据传输速度和设备响应效率。

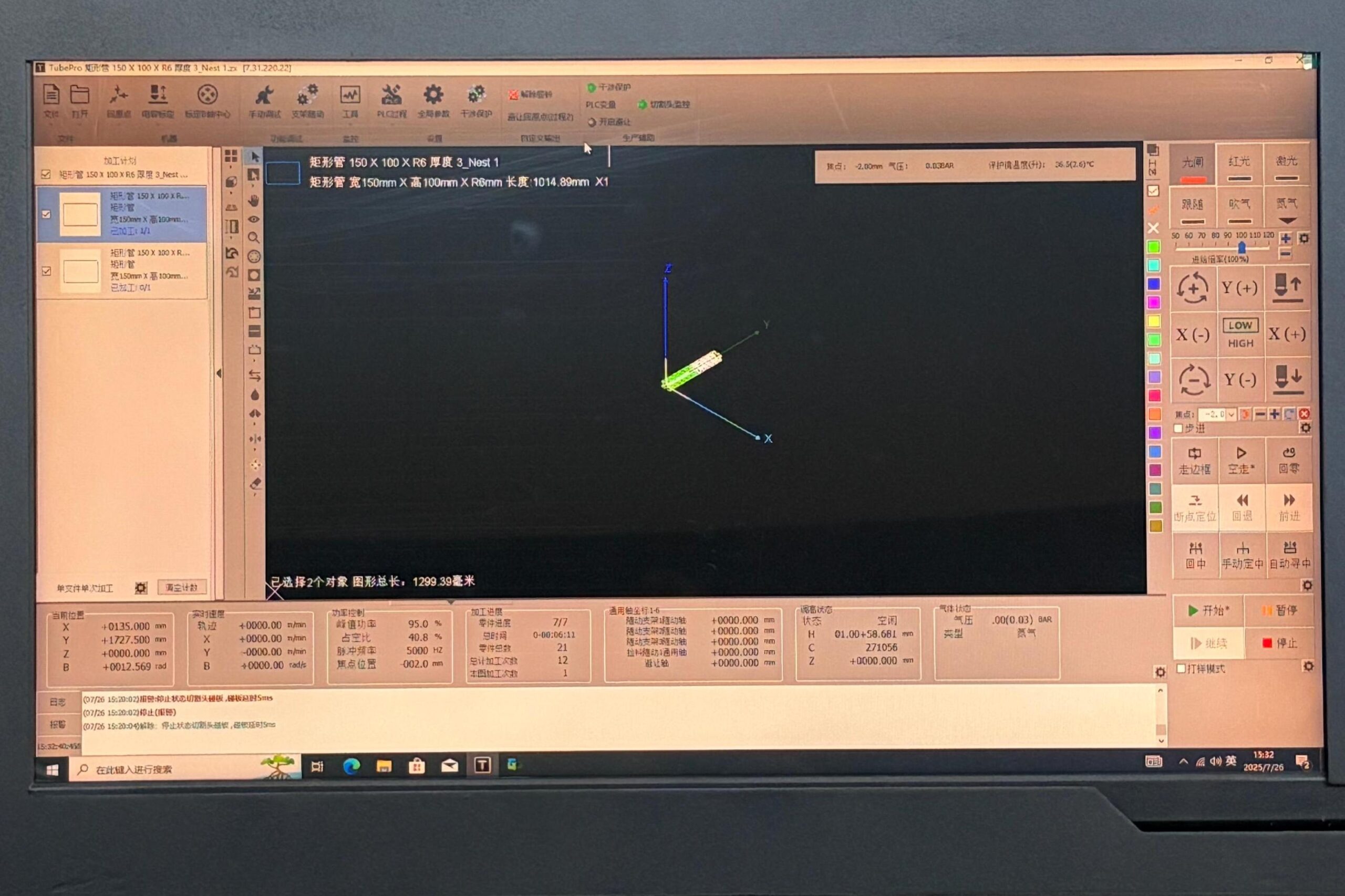

操作软件

界面友好,操作简便高效

软件直观易用,帮助用户快速掌握操作,提高工作效率。

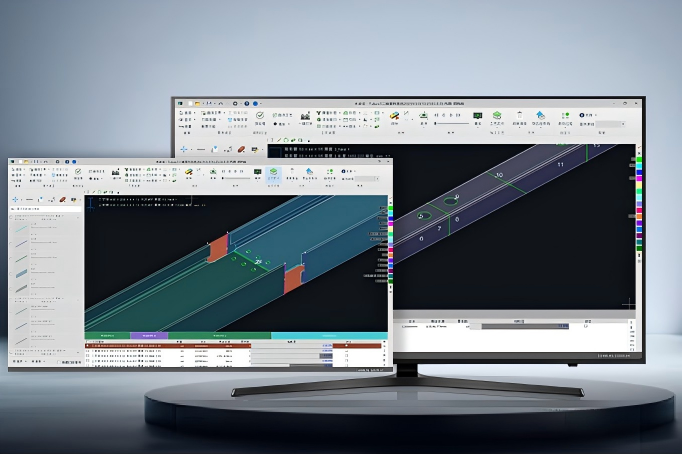

套料软件

优化排版,节省材料成本

套料软件通过智能算法优化排版,最大化材料利用率,降低成本。

电气系统

布局合理,运行可靠,减少故障发生,提升整体工作稳定性。

电控柜

合理布局,维护电路可靠性

电气负责为激光切割机的各个部件提供稳定的电力供应,协调各部分的信号传输和安全保护。

稳压器

平稳电压,防止损坏设备

稳压器确保电压恒定,保障敏感元件安全运行。

工控机

高速运算,支持复杂任务

工控机性能强劲,能快速处理复杂图形与数据运算任务。

显示器

高清呈现,便于监控操作

高清显示屏让操作更清晰直观,便于监控切割过程。

遥控手柄

灵活操作,提升便捷性

无线遥控手柄让操作者能远程操控设备,提升作业灵活度。

冷却系统

高效散热,防止过热,保障设备长时间稳定作业。

水冷机

高效制冷,保护核心部件

高效水冷机为激光器等核心部件提供稳定冷却,防止过热损坏。

电控柜换热器

可选的

控温精准,延长元件寿命

换热器精准控制电控柜内部温度,保护电子元件稳定运行。

供气系统

气压调节精准,使切割边缘更加整齐,提升加工效果。

气路阀组

精准控制,保障切割品质

气路阀组精确控制各路气体流量,确保切割质量和效率。

气压报警器

实时监控,保障作业安全

气压报警器可实时监测压力异常,及时预警保障操作安全。

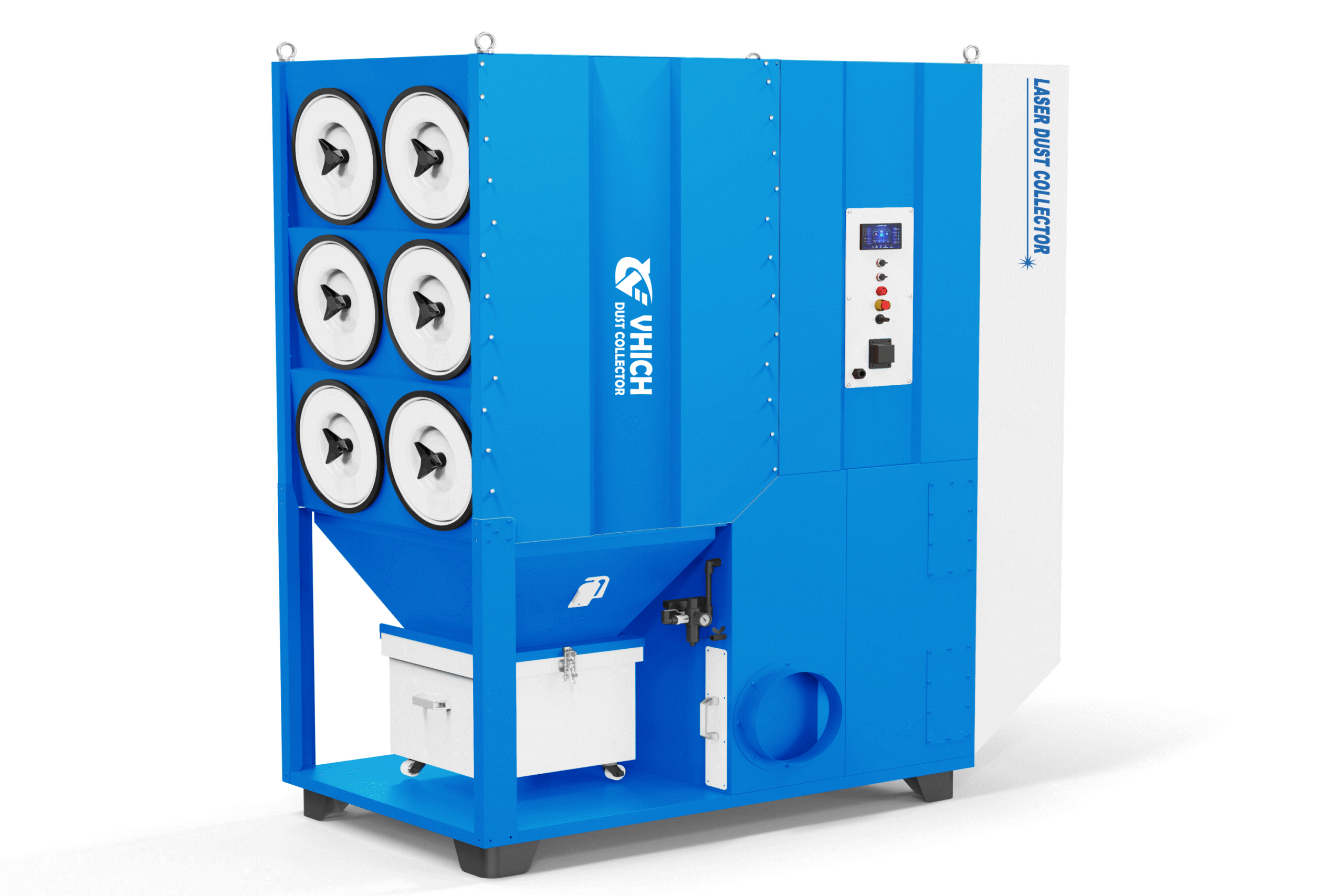

除尘系统

高效清除烟尘,保持环境清洁,并延长设备使用寿命。

除尘结构

高效排尘,保持清洁环境

优化的除尘结构快速排出烟尘,保证切割区清洁与视线通透。

离心风机

强力抽风,提升排尘效率

离心风机提供强大风力,提高废气排放速度和效率。

安全系统

多重防护降低风险,营造更安全的作业环境。

紧急停止

快速制动,保障人员安全

紧急停止装置可一键切断电源,确保突发情况下人员安全。

润滑系统

自动注油精准,减少磨损,降低维护成本,延长使用寿命。

润滑油泵

自动供油,减少维护成本

自动润滑系统定时注油,降低人工维护频率和成本。

收油装置

有效回收,环保无泄漏

收油装置高效回收余油,防止泄漏污染环境,提升环保水平。

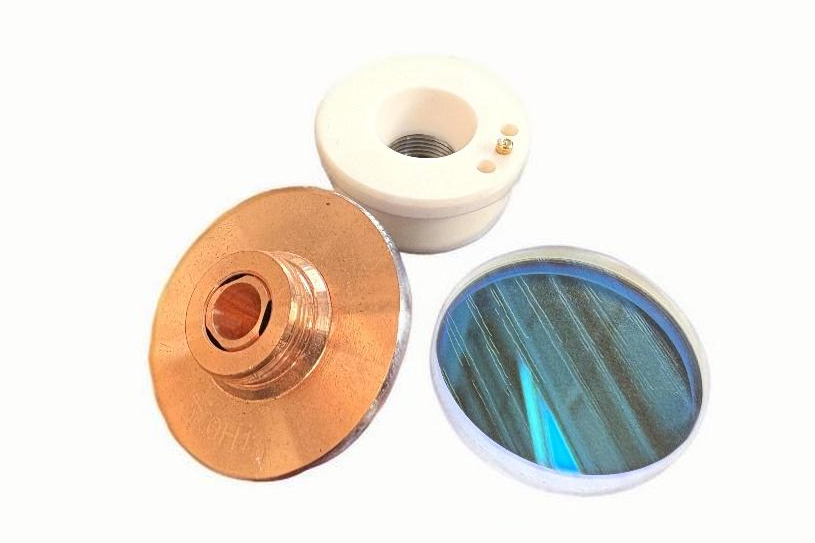

易损件

选用耐磨材料,更换简便,减少生产中断时间。

易损件套装

配件齐全,保障设备正常运行

标配易损件套装方便及时更换,降低停机风险。

可选配置

丰富配件灵活搭配,满足多样化加工需求,提升设备价值。

空压机

持续供气,满足工艺需求

空压机提供稳定气源,满足切割工艺对气压的持续需求。

半自动上料装置

简化上料,提升作业效率

半自动上料系统减少人工搬运,提升上料速度和效率。

自动上料装置

全自动运行,节省人工成本

自动上料系统实现管材自动分拣与上料,支持智能化生产。

产品技术规格

请查看你需要的技术细节,如果需要请联系我们。帮助中心

| 基本参数 | 管材最大长度 (mm) | 9000 |

| 管材尺寸范围 (mm) | ◯ 10 ~350mm ▢ 10~350mm |

|

| 管材最大重量 (kg) | 900 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 36000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 80 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

| 基本参数 | 管材最大长度 (mm) | 9000 |

| 管材尺寸范围 (mm) | ◯ 25 ~520mm ▢ 25~520mm |

|

| 管材最大重量 (kg) | 1500 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 36000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 60 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

| 基本参数 | 管材最大长度 (mm) | 9000 |

| 管材尺寸范围 (mm) | ◯ 80 ~640mm ▢ 80~640mm |

|

| 管材最大重量 (kg) | 1800 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 36000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 40 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

| 基本参数 | 管材最大长度 (mm) | 12000mm |

| 管材尺寸范围 (mm) | ◯ 10 ~350mm ▢ 10~350mm |

|

| 管材最大重量 (kg) | 1200 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 46000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 80 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

| 基本参数 | 管材最大长度 (mm) | 12000mm |

| 管材尺寸范围 (mm) | ◯ 25 ~520mm ▢ 25~520mm |

|

| 管材最大重量 (kg) | 2000 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 46000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 60 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

| 基本参数 | 管材最大长度 (mm) | 12000mm |

| 管材尺寸范围 (mm) | ◯ 80 ~640mm ▢ 80~640mm |

|

| 管材最大重量 (kg) | 2500 | |

| 最短余料 (mm) | 零尾料 | |

| 机床外形尺寸 (mm) | 46000*2100*3000 | |

| 性能 | 激光头移动轴最大速度 (m/min) | 100 |

| 激光头移动轴最大加速度 (m/s²) | 0.8G | |

| 卡盘最大转速 (r/min) | 160 | |

| 卡盘送料轴最大速度 (m/min) | 40 | |

| 卡盘送料轴最大加速度 (m/s²) | 1.0G | |

| 定位精度 (mm) | ±0.05 | |

| 重复定位精度 (mm) | ±0.02 |

Get in Touch with Us Now!

Please fill in the form and describe your requirements. Our team will get back to you within 24 hours.