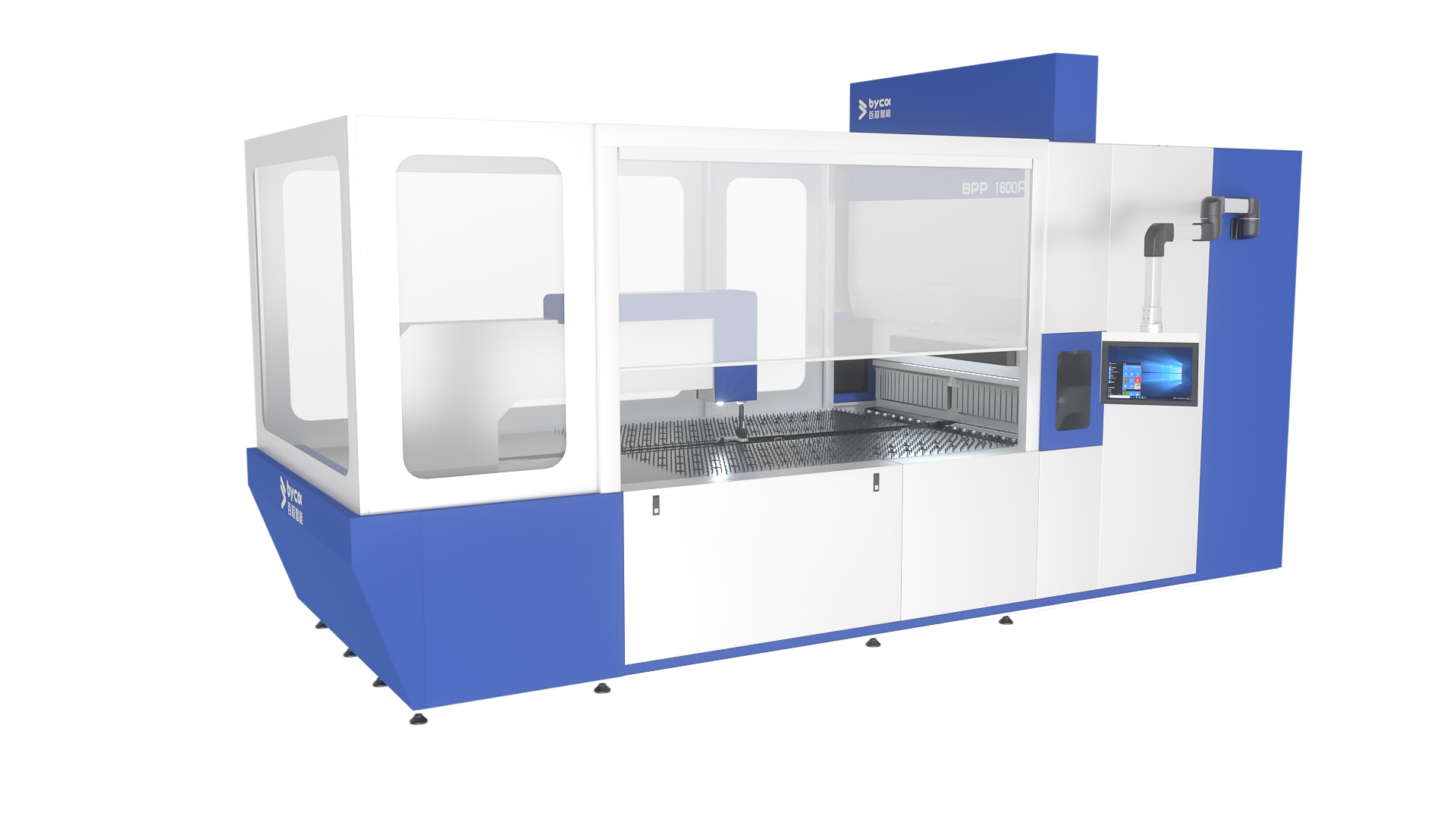

BPP 系列 压臂式自动折弯中心

选择压臂式自动折弯中心,实现多边自动折弯与高效成型,大幅提升箱体柜体加工精度与生产效率,是智能化生产的理想选择。

机械系统

设备具备良好的刚性与稳定性,可在长时间、高强度运行中保持折弯精度和结构可靠性。

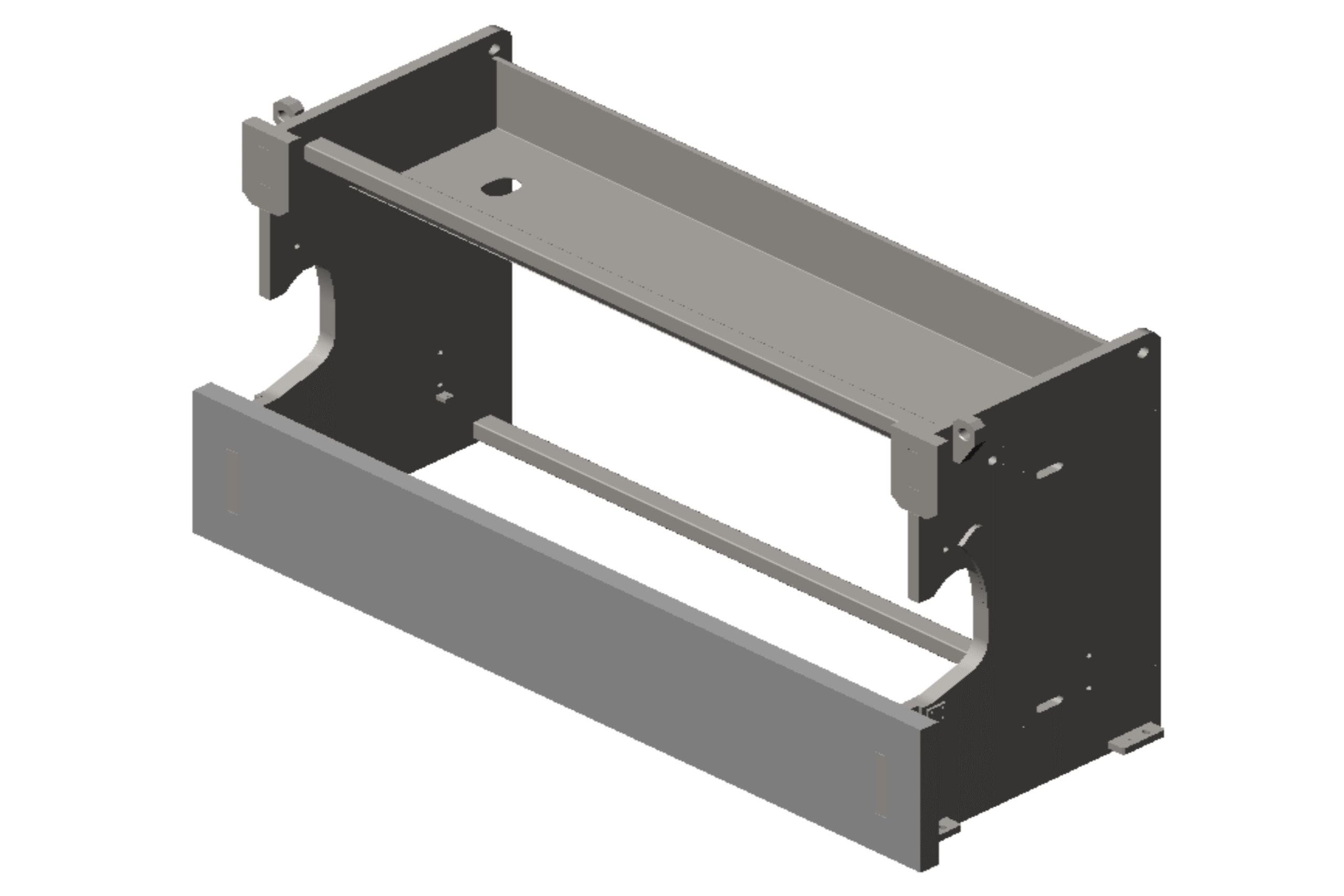

床身

高刚性设计保障稳定性

床身采用高强度钢结构设计,具备优异的承载能力和抗变形性能。

压臂结构

支撑稳固,提升操作便捷性

压臂用于支撑工业触控屏与数控系统,结构坚固,角度可调,方便操作人员根据使用习惯进行调节。

工作台

平稳支撑保障折弯精度

工作台表面平整、刚性强,能够为工件提供稳定支撑,有效避免因工件晃动而影响折弯精度,确保加工一致性。

托料装置

可选的

辅助支撑,减轻人工疲劳

托料装置为大型工件提供可靠支撑,避免材料下垂导致角度误差,减轻人工操作强度。

驾驶系统

具备快速定位与高重复精度能力,能适应不同尺寸工件的加工需求,有效提高生产效率。

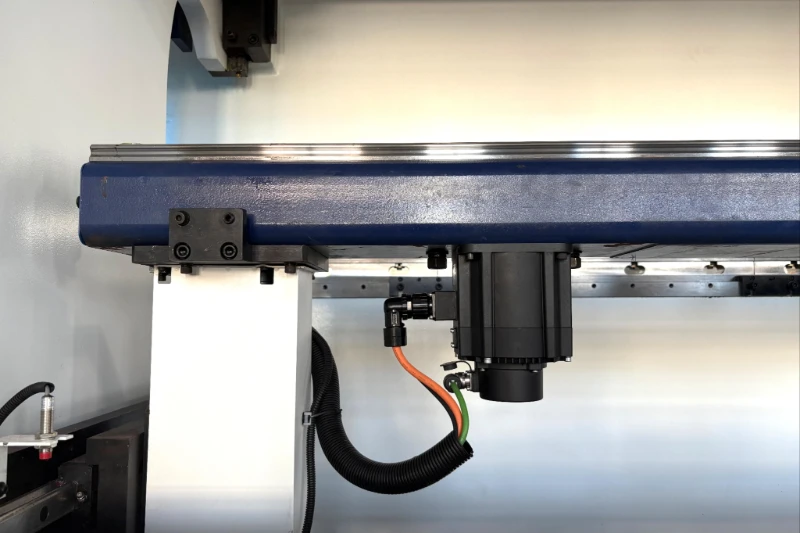

伺服电机/驱动

控制挡料运动,实现快速精准定位

伺服电机与驱动系统控制后挡料快速精准移动,实现高效定位与自动化折弯流程,提升加工效率与一致性。

直线导轨

引导平稳滑动,延长系统使用寿命

直线导轨提供平稳顺畅的滑动路径,减少摩擦与运行阻力,延长后挡料机构的使用寿命。

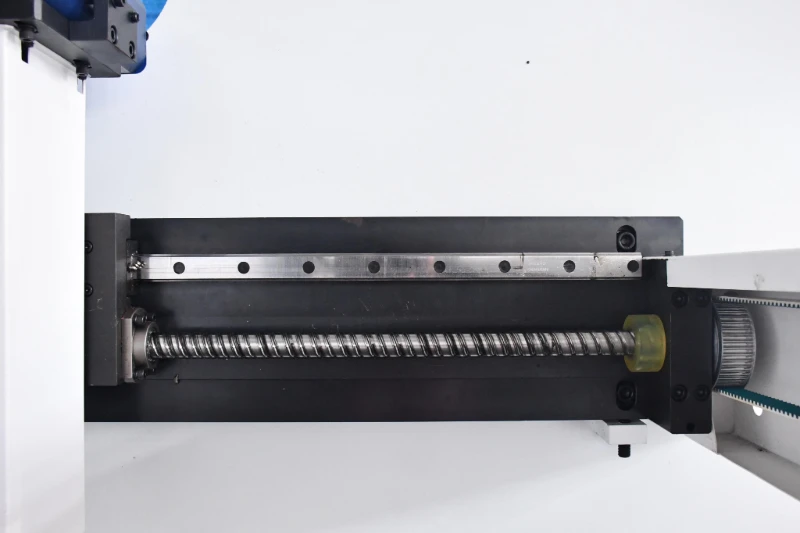

滚珠丝杆

高精传动结构,保障重复定位一致

滚珠丝杆传动精度高,确保后挡料系统在反复定位中保持高度一致性。

控制系统

支持图形化编程与多轴协调控制,操作简洁直观,显著提升自动化水平与加工一致性。

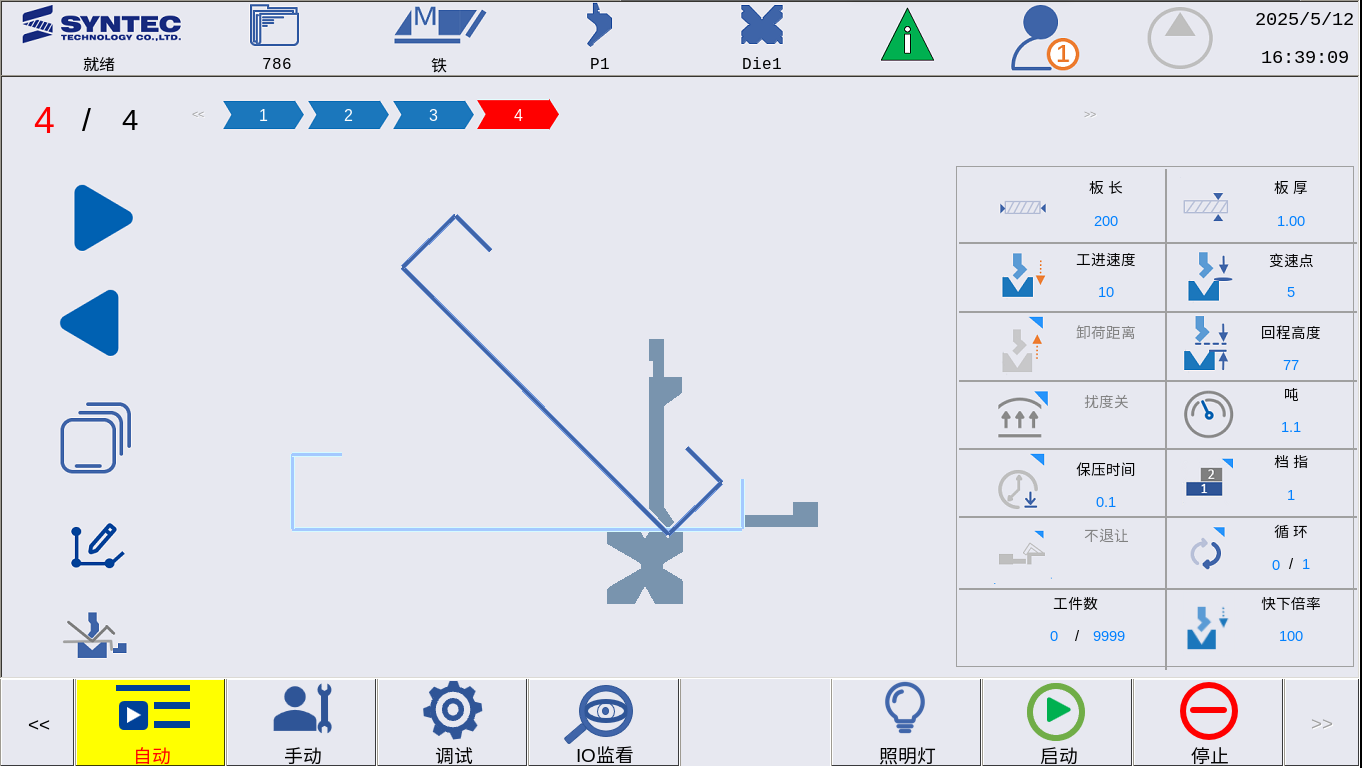

数控系统

可选的

支持智能编程,实现多轴同步控制

数控系统具备强大的图形编程与多轴联动能力,可实现多工步自动运行,提高加工的自动化和灵活性。

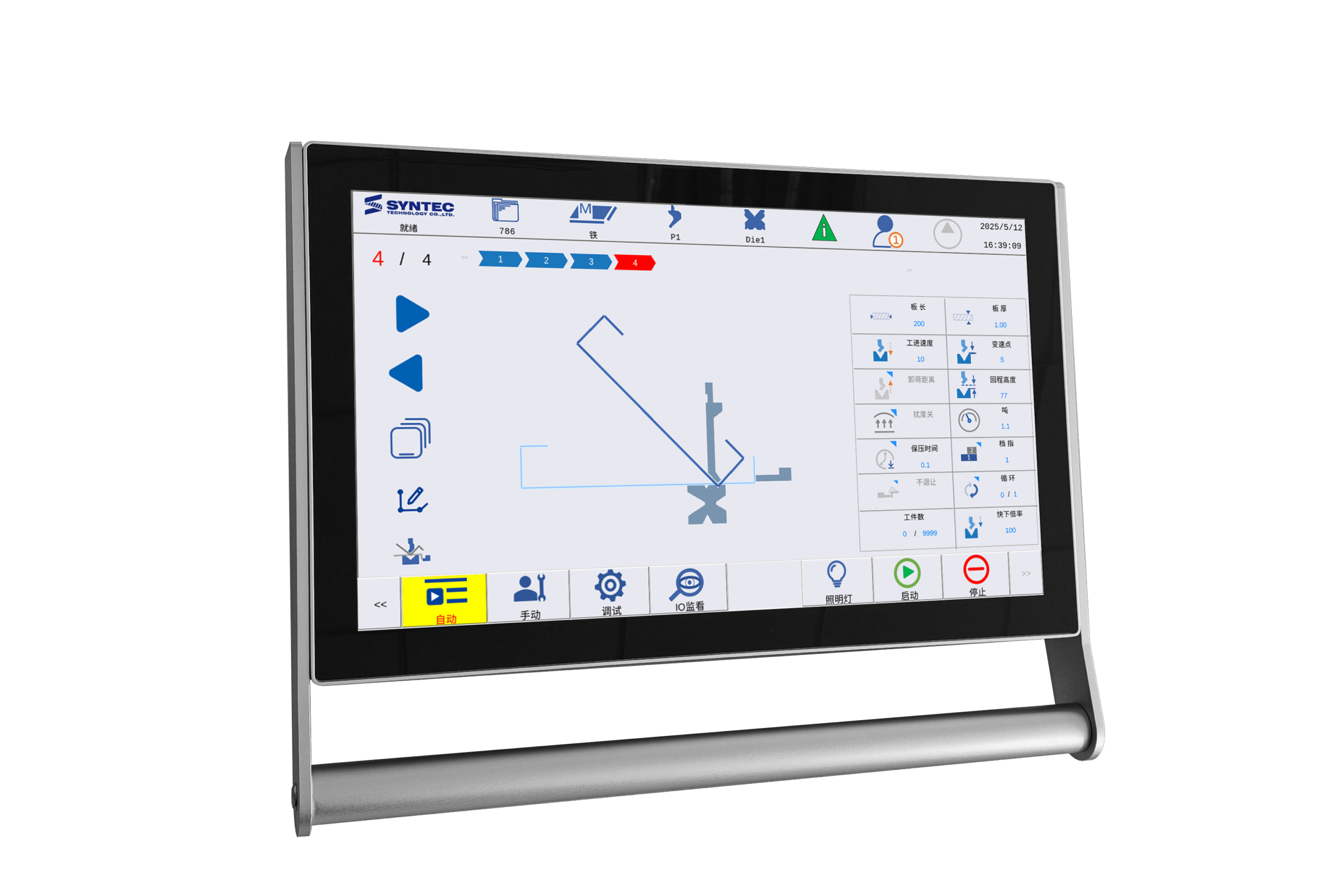

工业触控屏

界面直观提升操作体验

触控屏操作界面直观清晰,反应灵敏,便于操作者设置参数、监控设备状态以及运行操作。

电气系统

系统布局合理,接线清晰,具备良好的安全性与维护性,可确保设备长期稳定运行。

电气

集中布线设计,方便维护与检修

电控柜内部元件布局合理、布线清晰,便于日常检查与维护,同时有效提升系统运行的安全性。

LED照明

高亮照明保障工作可视

工作区域内配备高亮LED照明系统,即使在低光环境下也能保障良好的视野,便于细节观察与安全作业。

模具系统

支持快速更换与多模具兼容性,可满足不同材料与工艺的折弯应用,提升设备灵活性。

模具

可选的

结构精准耐用,满足多种折弯需求

模具种类丰富,可适配不同材料与工艺要求,满足多样化的折弯加工需求。

安全系统

通过多项主动与被动防护机制,有效降低误操作风险,保障人员与设备的运行安全。

紧急停止

一键断电快速停止运行

配备急停按钮,可在突发异常情况下一键中断所有动作,保护操作人员和设备免受损害。

脚踏开关

释放双手控制,提高操作效率

脚踏开关控制灵活,便于操作者在保证安全的前提下高效完成折弯作业。

辅助系统

可集成多种智能辅助装置,实现自动上下料与运行环境调控,进一步提升产线智能化水平。

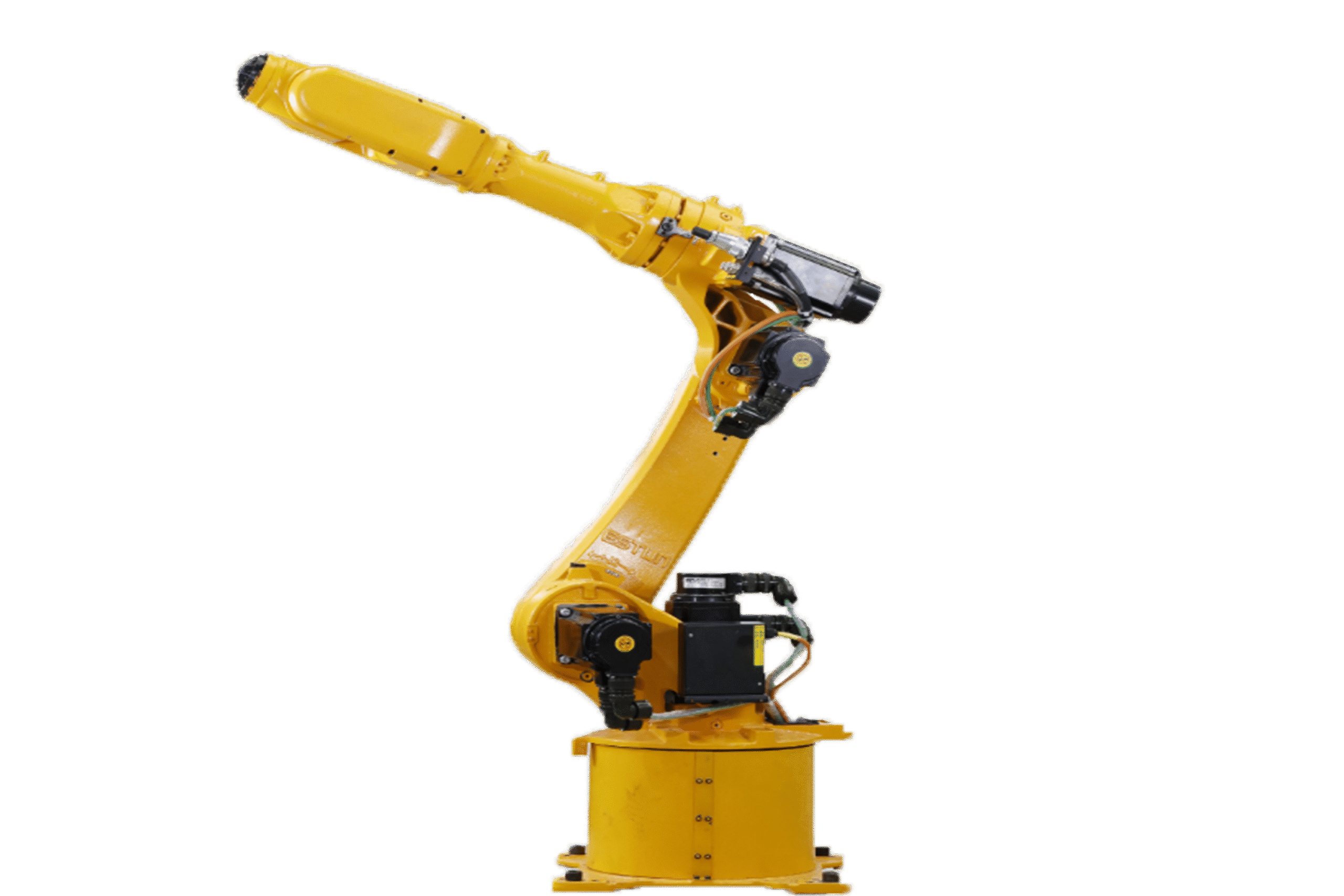

机器人

自动上下料折弯,实现智能生产

工业机器人可自动完成上下料与折弯任务,支持与主机联动运行,打造高效、智能化的柔性生产线。

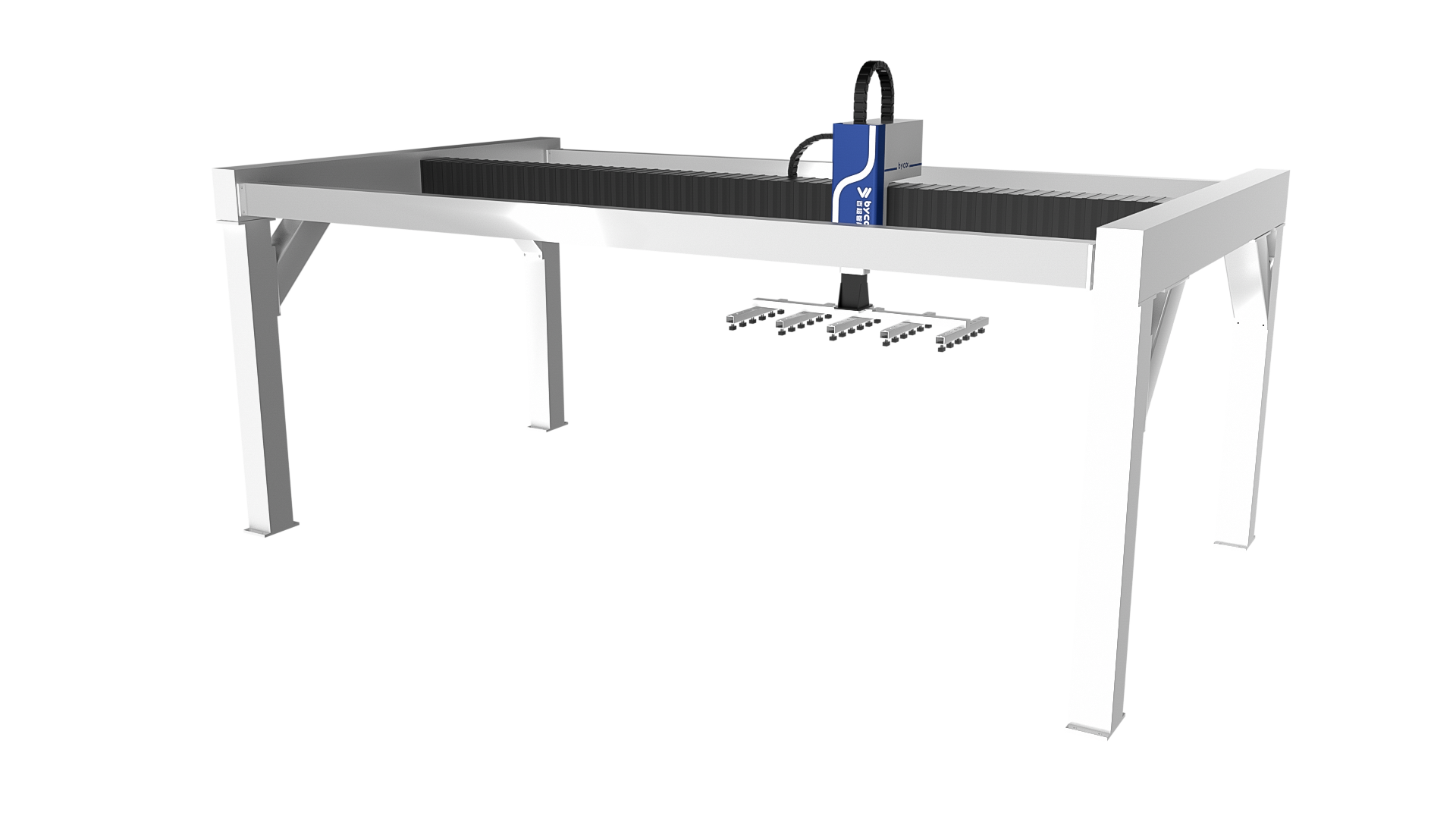

龙门式上下料系统

大幅提高产出,投资回报率高

无缝衔接折弯中心,极速完成上下料,将设备有效工作时间最大化,显著提高整体产能,快速收回投资。

产品技术规格

请查看你需要的技术细节,如果需要请联系我们。帮助中心

| 基本参数 | 最大折弯长度 (mm) | 1600 |

| 最大折弯高度 (mm) | 180 | |

| 折弯厚度 (mm) | 抗拉强度 650N/mm² 304 不锈钢: 0.3~2mm 抗拉强度 450N/mm² 冷板: 0.3~3mm 抗拉强度 210N/mm² 铝板: 0.3~4mm |

|

| 电机功率 (kW) | 75 | |

| 外形尺寸 (mm) | 5200*2000*3200 | |

| 性能 | 最快单次折弯时间 (s) | 0.2 |

| 最大旋转直径 (mm) | 2050 | |

| 定位宽度 (mm) | 200~1650 | |

| 单边最小成型尺寸 (mm) | 170 | |

| 双边最小成型尺寸 (mm) | 200 | |

| 四边最小成型尺寸 (mm) | 200*200 | |

| 折弯角度 (°) | 0 ~ 180° |

| 基本参数 | 最大折弯长度 (mm) | 2000 |

| 最大折弯高度 (mm) | 180 | |

| 折弯厚度 (mm) | 抗拉强度 650N/mm² 304 不锈钢: 0.3~2mm 抗拉强度 450N/mm² 冷板: 0.3~3mm 抗拉强度 210N/mm² 铝板: 0.3~4mm |

|

| 电机功率 (kW) | 75 | |

| 外形尺寸 (mm) | 6200*2500*3200 | |

| 性能 | 最快单次折弯时间 (s) | 0.2 |

| 最大旋转直径 (mm) | 2400 | |

| 定位宽度 (mm) | 200~2050 | |

| 单边最小成型尺寸 (mm) | 170 | |

| 双边最小成型尺寸 (mm) | 200 | |

| 四边最小成型尺寸 (mm) | 200*200 | |

| 折弯角度 (°) | 0 ~ 180° |

| 基本参数 | 最大折弯长度 (mm) | 2500 |

| 最大折弯高度 (mm) | 180 | |

| 折弯厚度 (mm) | 抗拉强度 650N/mm² 304 不锈钢: 0.3~2mm 抗拉强度 450N/mm² 冷板: 0.3~3mm 抗拉强度 210N/mm² 铝板: 0.3~4mm |

|

| 电机功率 (kW) | 110 | |

| 外形尺寸 (mm) | 7200*3200*3200 | |

| 性能 | 最快单次折弯时间 (s) | 0.2 |

| 最大旋转直径 (mm) | 2800 | |

| 定位宽度 (mm) | 200~2550 | |

| 单边最小成型尺寸 (mm) | 170 | |

| 双边最小成型尺寸 (mm) | 200 | |

| 四边最小成型尺寸 (mm) | 200*200 | |

| 折弯角度 (°) | 0 ~ 180° |

| 基本参数 | 最大折弯长度 (mm) | 3000 |

| 最大折弯高度 (mm) | 180 | |

| 折弯厚度 (mm) | 抗拉强度 650N/mm² 304 不锈钢: 0.3~2mm 抗拉强度 450N/mm² 冷板: 0.3~3mm 抗拉强度 210N/mm² 铝板: 0.3~4mm |

|

| 电机功率 (kW) | 110 | |

| 外形尺寸 (mm) | 8200*3900*3200 | |

| 性能 | 最快单次折弯时间 (s) | 0.2 |

| 最大旋转直径 (mm) | 3300 | |

| 定位宽度 (mm) | 200~3050 | |

| 单边最小成型尺寸 (mm) | 170 | |

| 双边最小成型尺寸 (mm) | 200 | |

| 四边最小成型尺寸 (mm) | 200*200 | |

| 折弯角度 (°) | 0 ~ 180° |

Get in Touch with Us Now!

Please fill in the form and describe your requirements. Our team will get back to you within 24 hours.