This morning, the grand opening ceremony of the Smart Manufacturing Base of Byca was held at its nenanw location in Lishui District, Nanjing. The company’s entire staff, along with local government leaders from Lishui, industry association representatives, partners, and media guests, gathered together to witness this important milestone in the company’s strategic development. The full-scale commissioning of the new base marks a significant leap forward in the company’s R&D and manufacturing capabilities in the high-end equipment fields of laser cutting and sheet metal bending.

I. Opening Ceremony: Government and Enterprise Unite to Chart the Smart Manufacturing Blueprint

1. Corporate Address: Building on a New Foundation, Planning a New Future

During the opening ceremony, General Manager Zhang Wei delivered a speech in which he first reviewed the company’s development journey from its founding to its current growth, extending sincere gratitude to all colleagues involved in the construction. He emphasized that the completion of the new smart manufacturing base is far from a simple expansion of production scale; it represents a strategic pivot for the company to achieve comprehensive technological upgrading and deep intelligent transformation.

General Manager Zhang stated, “This new base will serve as our core platform for integrating cutting-edge technologies, lean manufacturing, and digital management. In the future, we will remain steadfast in focusing on the R&D directions of ‘high precision, intelligence, and flexibility,’ continuously breaking through key technologies and refining our process systems.” The company aims to provide more advanced and reliable integrated laser cutting and bending solutions, deeply empowering customers to enhance lean production and flexible manufacturing, and jointly embrace the new opportunities presented by the high-quality development of modern manufacturing.

2. Government Message: Rooted in the Local Soil, Injecting New Momentum for Development

A representative of the local government delivered a warm congratulatory speech at the ceremony. He first expressed hearty congratulations on the successful completion of Byca’s smart manufacturing base and highly commended the company’s leading role as a backbone enterprise in the local high-end equipment manufacturing sector.

In his address, the leader noted, “The completion and operation of this smart manufacturing base not only reflects the company’s exceptional strategic vision and innovative capabilities but also aligns closely with our city’s overall plan to prioritize the development of advanced manufacturing and promote industrial upgrading. The project will effectively drive the agglomeration and development of related supporting industrial chains, injecting strong momentum into the intelligent transformation of regional manufacturing.” He further stated that the government will continue to optimize the business environment, providing solid support in terms of policy assistance, talent recruitment, and supporting services, fully backing the company in deepening its core technologies and expanding its market advantages. The government looks forward to the company becoming an industry benchmark in the future, contributing even greater strength to the high-quality development of the regional economy.

II. Core Highlights: Showcasing Advanced Products and Smart Manufacturing Strength

A key segment of the ceremony was the presentation of future-oriented products and technologies.

1. Unveiling Flagship Products: Leading the Technological Frontier

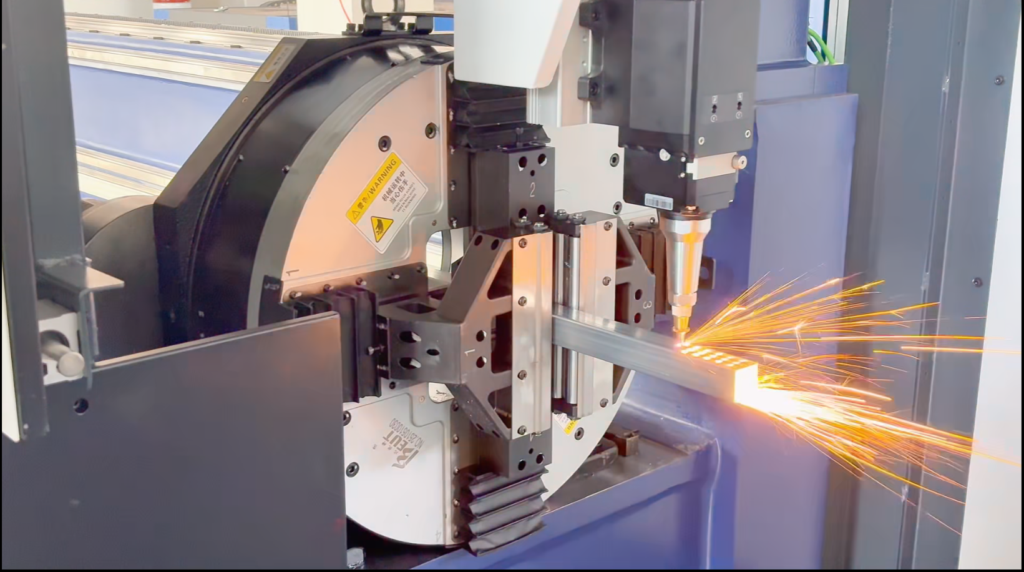

The “Laser” series of ultra-high-power laser cutting machines, equipped with Byca’s advanced intelligent CNC system, leverages its built-in intelligent piercing and cutting process database to adaptively optimize parameters for plates of different thicknesses and materials. These machines excel in thick-plate cutting, enabling stable, efficient penetration and cutting of heavy materials such as stainless steel and carbon steel while ensuring smooth, high-precision cuts. For special materials like aluminum and alloys, their customized process solutions effectively control the heat-affected zone, improving processing quality and efficiency, fully meeting the demands of high-end manufacturing for precision machining.

The “Bending” series of ultra-high-precision electro-hydraulic CNC bending machines utilize advanced electro-hydraulic servo control and a high-rigidity frame structure to achieve micron-level high repeatability and long-term operational stability. These machines perform exceptionally well in complex sheet metal forming processes, capable of both high-precision linear bending and handling complex tasks such as multi-step bending and special-shaped forming. Their energy-saving and environmentally friendly design significantly reduces energy consumption and noise, and when paired with intelligent programming systems, they greatly enhance production efficiency and workpiece consistency, making them a reliable choice for the sheet metal processing industry’s transition toward intelligent and green production.

2. A Glimpse into the Smart Factory: Interpreting a New Manufacturing Paradigm

During the visit to the smart workshop, guests had the opportunity to observe the preliminary smart manufacturing framework integrating automated production lines, intelligent material storage systems, and a unified digital management platform. The new base, centered around a Manufacturing Execution System (MES) and deeply integrated with IoT technology and real-time data collection, establishes a digital control network covering all production stages.

Through this system, the enterprise can achieve traceable and transparent management across the entire process—from order receipt, production scheduling, and material allocation to production execution, quality tracking, and logistics delivery. This framework not only enhances the controllability and responsiveness of the production process but also provides reliable data support for continuous process optimization and energy consumption reduction, marking a solid step forward in the company’s transition toward flexible and intelligent manufacturing.

III. Cornerstone Strength: An Excellent Team and the Spirit of Craftsmanship

The company’s success is rooted in the dedication of every employee.

1. Employee Showcase: Pride and Responsibility in Action

During the event, representatives from the R&D and production lines took the stage to share their memorable experiences participating in the planning, construction, production line layout, and commissioning of core equipment for the new factory. From the repeated discussions of early technical solutions to round-the-clock dedication during installation and the relentless pursuit of excellence during trial production, every phase embodied the team’s hard work and wisdom. Their stories were sincere and vivid, naturally conveying unwavering confidence in the company’s independently innovative products and fervent anticipation for its future development. This sense of belonging and responsibility fully reflects the employees’ ownership spirit and demonstrates their profound professional competence and tenacious problem-solving demeanor, serving as the company’s most precious internal driving force.

2. Team Photo: Capturing a Historic Moment

As the ceremony drew to a close, all attending employees, leaders, and guests gathered in front of the magnificent new factory building to take a commemorative “family photo.” Bathed in sunlight, the new base shone brightly as the camera captured each hopeful and proud smile. This photograph not only faithfully documents the historic moment of the official opening of the company’s new manufacturing base but also deeply encapsulates the collective effort and wisdom of all colleagues from blueprint planning to completion. It symbolizes the beginning of a new journey and vividly illustrates the deep camaraderie and unwavering determination of the entire company to unite and share the mission. All employees will take this as a new starting point, continuing to strive and jointly create a brilliant future for the enterprise.

IV. Official Launch: Ribbon-Cutting Ceremony and Tour Exchange

Amidst great anticipation, General Manager Zhang and key local leaders jointly held golden scissors to cut the ribbon for the completion of the smart manufacturing base. As the bright red ribbon fell, festive fireworks lit up the sky, and the venue erupted with thunderous applause and cheers. This solemn yet exuberant moment officially heralded Byca’s entry into a new phase of smart manufacturing development, unveiling a strategic new chapter for the company as it establishes its presence in East China and radiates its influence nationwide.

Following the successful ribbon-cutting ceremony, guests, guided by the company’s team, proceeded to the meticulously arranged product exhibition hall and modern production areas for an in-depth tour and exchange. In the exhibition hall, guests observed high-end equipment representing industry-leading technologies, such as laser cutting and CNC bending machines, up close and listened to detailed technical explanations. In the production workshop, the smooth operation of automated production lines and the precise control of intelligent systems vividly demonstrated the company’s smart manufacturing philosophy and practical achievements. Throughout the tour, guests frequently paused for discussions, offering high recognition and praise for the company’s robust capabilities and forward-thinking approach in core technologies, product performance, and overall intelligent transformation.sthand the advanced capabilities of the new facility.