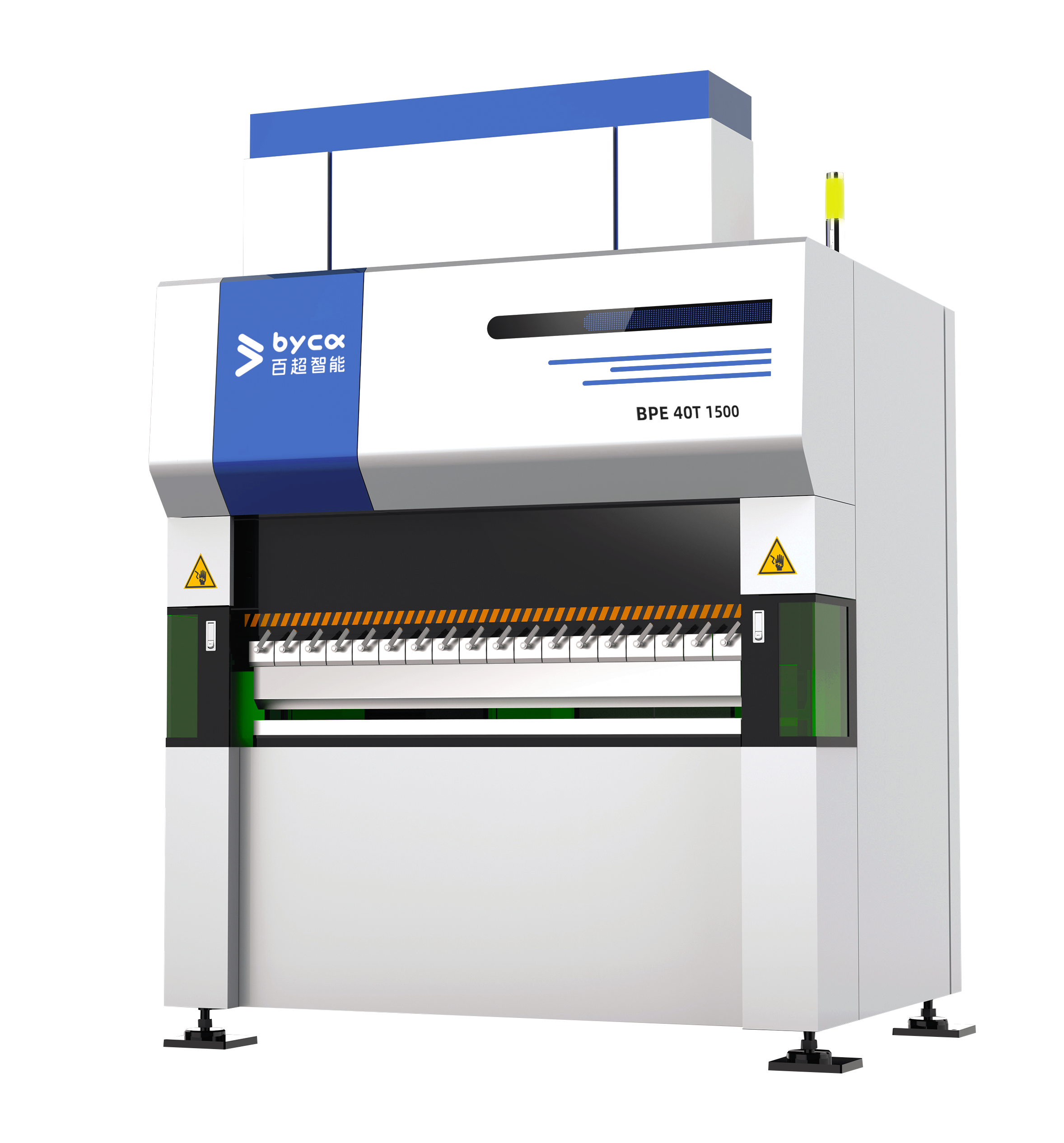

BPE Series Electric Servo CNC Press Brake Machine

Choose the Electric Servo Press Brake for zero standby consumption, rapid response, and quiet operation – achieving higher efficiency and lower costs for competitive advantage.

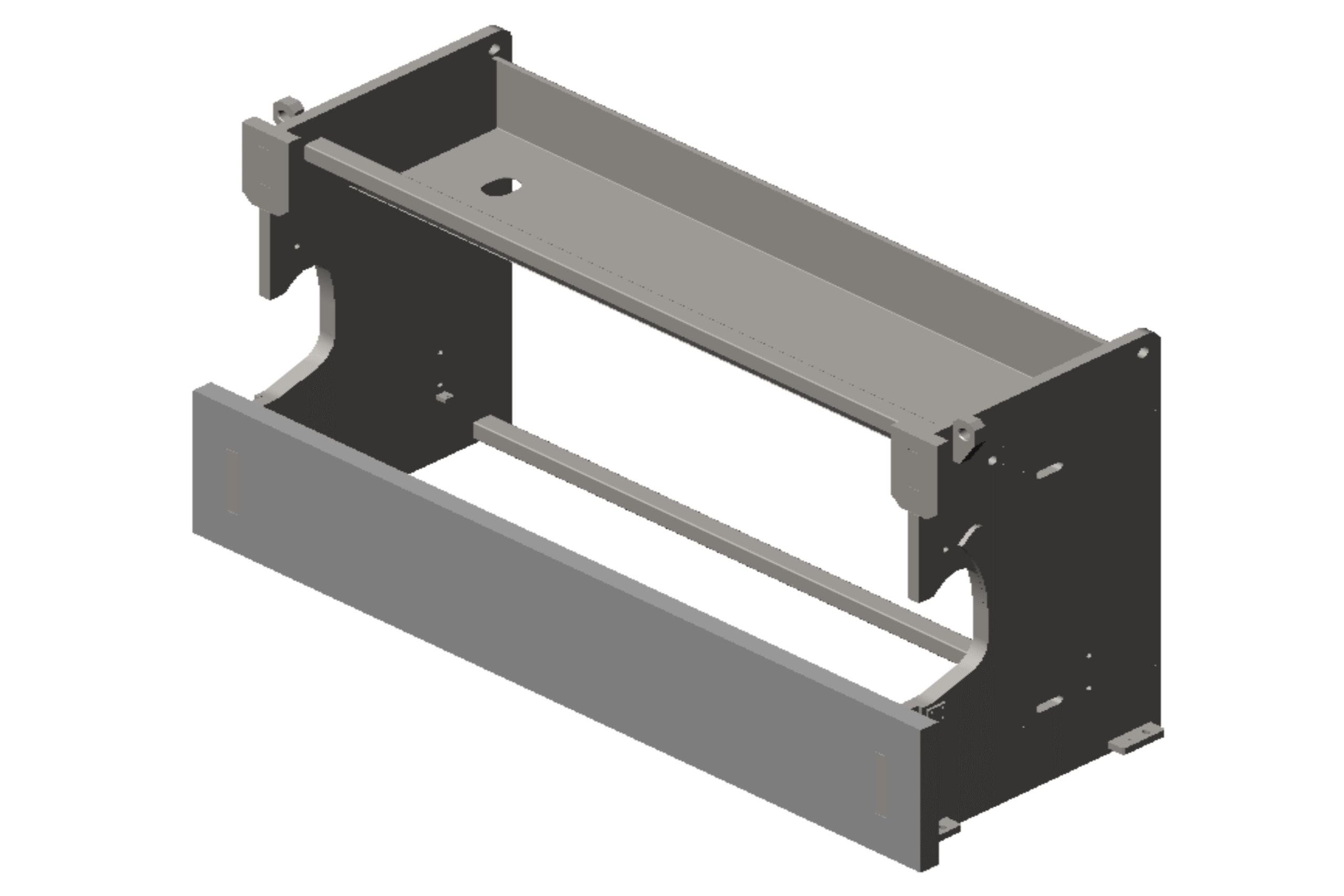

Mechanical System

The system provides excellent rigidity and stability, ensuring bending accuracy and structural reliability during long-term, high-load operation.

BED

Rigid design ensures stability

The bed is designed with high-strength steel structure, featuring excellent load-bearing capacity and anti-deformation performance.

Control Pendant Arm

Stable support improves operation convenience

The Control Pendant Arm holds the touch screen and CNC unit, allowing adjustable angles for optimal ergonomics.

Working Table

Stable support ensures precision

The flat and rigid surface supports the workpiece securely, preventing movement that may affect bending consistency.

Linear ENCODER

Real-time position feedback enhances control accuracy

It collects slide displacement data and works with the CNC system for precise closed-loop position control.

Support Arm

Optional

Auxiliary support reduces operator fatigue

It provides reliable support for oversized parts, preventing sagging and reducing manual handling effort.

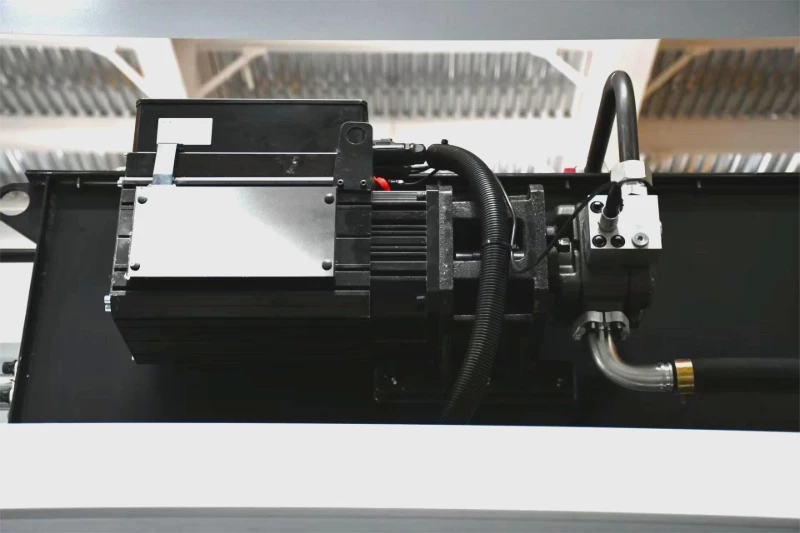

Drive System

With servo-controlled technology, the system delivers stable power output and rapid response for efficient, energy-saving, and precise bending.

Main Servo Motor

Drives the hydraulic system for efficient bending

Delivers high torque and fast response, powering the hydraulic cylinder for precision bending operations.

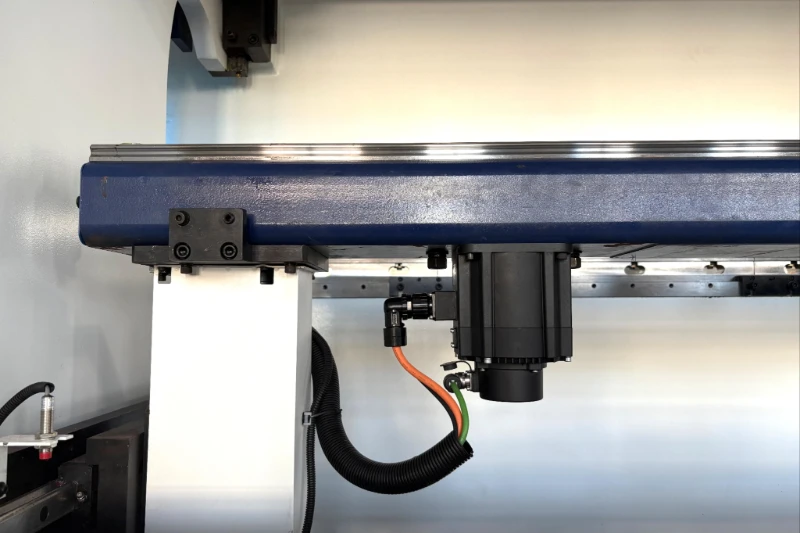

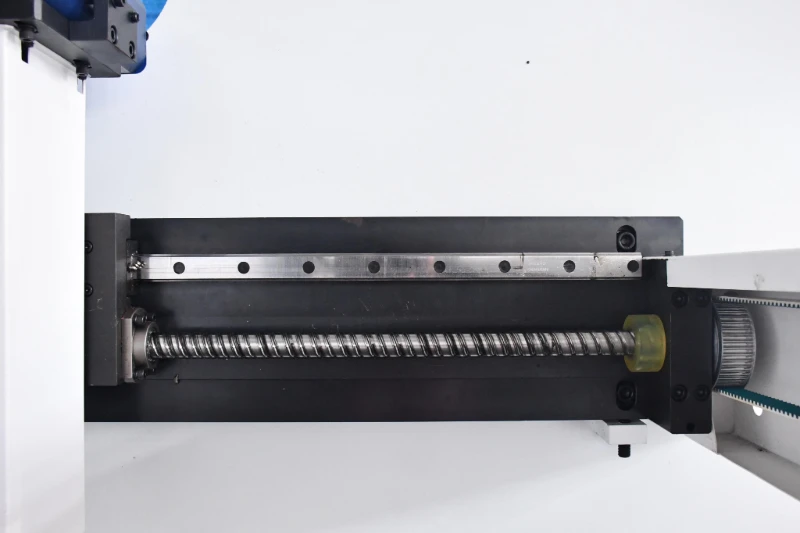

Backgauge System

The system offers fast positioning and high repeatability to handle various workpiece sizes efficiently and accurately.

Servo Motor & Drive

Controls gauge movement for accurate positioning

It enables fast, precise motion of the backgauge, improving setup efficiency and consistency.

Linear Guide Rail

Guides smooth movement and extends service life

Provides low-friction motion to reduce wear and maintain long-term alignment.

Ball Screw

High-precision transmission for repeatable positioning

Delivers accurate motion control for reliable and consistent backgauge performance during repeated positioning.

Back Gauge Finger

Adjustable positioning to fit various workpieces

Flexible positioning allows compatibility with different workpiece sizes and shapes.

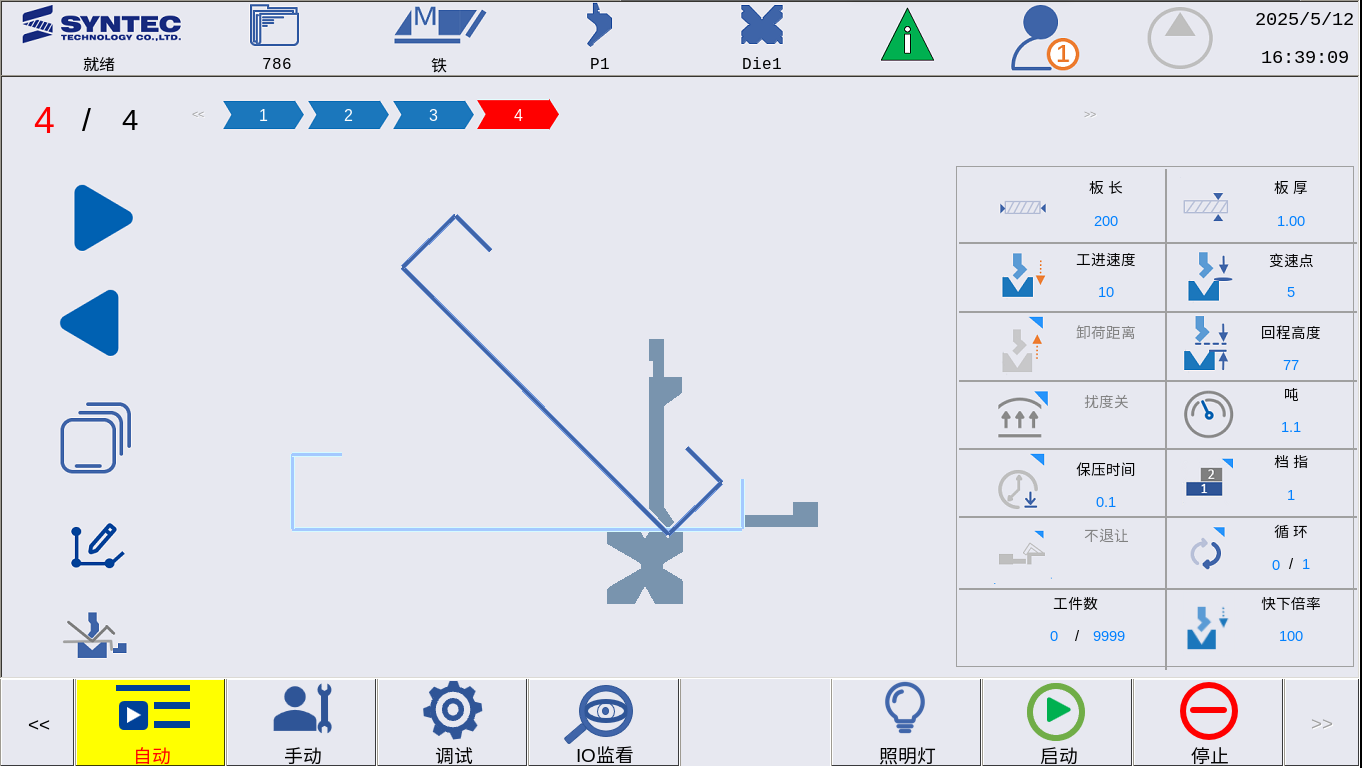

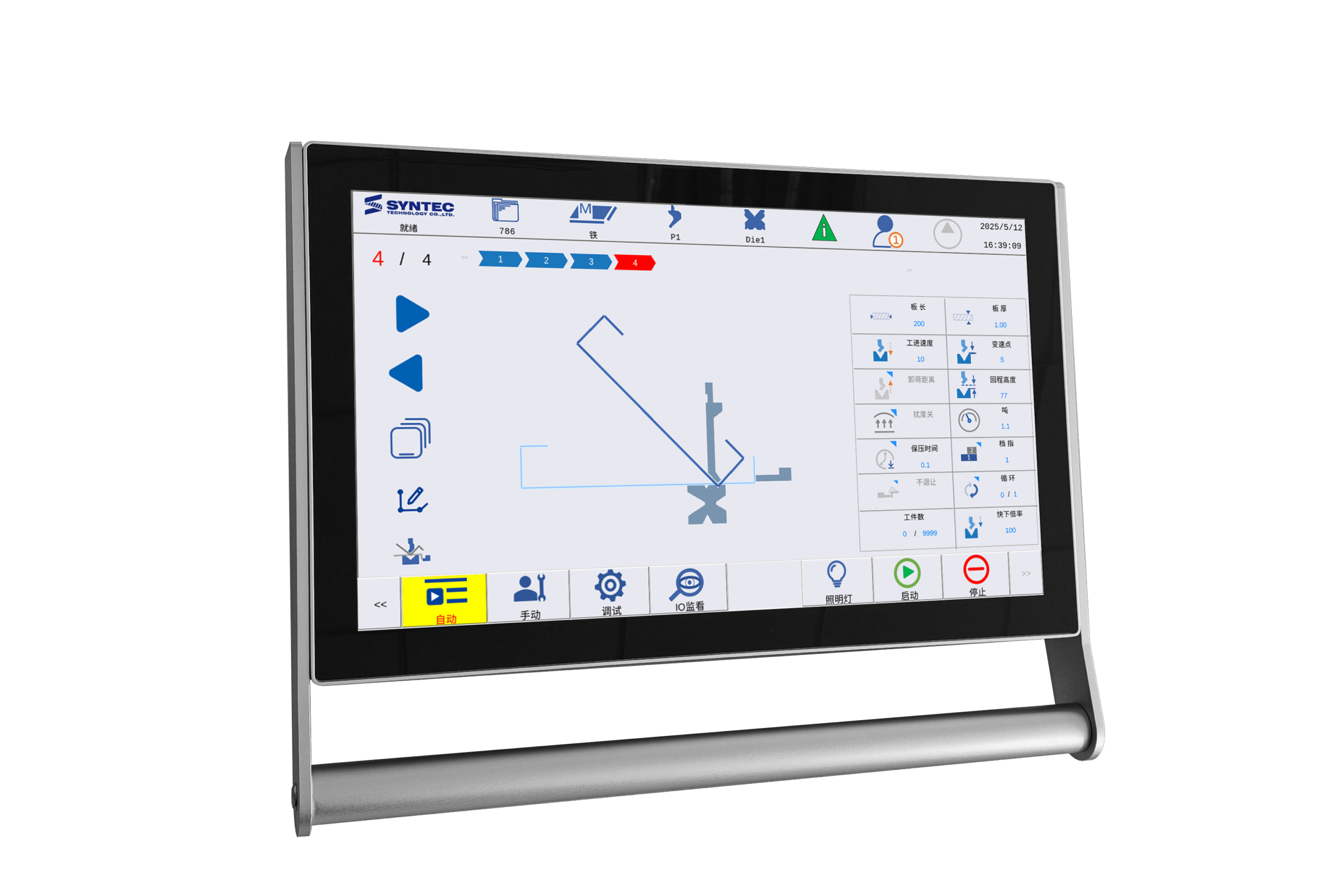

Control System

Supporting graphical programming and multi-axis coordination, the system simplifies operation and significantly enhances automation and processing consistency.

CNC Controller

Optional

Enables graphic programming and multi-axis coordination

Supports graphic programming and multi-axis linkage capabilities for flexible and automated operation.

HMI Touch Panel

Intuitive interface enhances user experience

Features a clear and responsive touchscreen for real-time settings, monitoring, and operation.

Electrical System

Featuring a clean and organized layout, the system ensures electrical safety, easy maintenance, and long-term operational stability.

Electrical

Organized wiring for safe, easy maintenance

Integrates all key electrical components with neat layout, enhancing safety and maintenance convenience.

LED Work Area Light

Bright lighting improves workspace visibility

Ensures a good field of vision even in low-light conditions, facilitating detailed observation and safe operation.

Tooling System

The system allows quick changeovers and compatibility with various tools, improving flexibility for diverse bending applications.

Quick Clamp

Optional

One-touch clamping boosts changeover efficiency

Allows quick and secure mold replacement, reducing downtime and increasing productivity.

Mold

Optional

Durable and precise for various bending needs

There are a wide variety of molds available, which can be adapted to different materials and process requirements.

Safety System

With multiple active and passive protections, the system minimizes operational risks and ensures safety for both operator and equipment.

Front Guard Protection

Optional

Real-time detection to prevent injury

Safety light curtain detect intrusions and abnormal operation,and instantly stop machine motion to ensure operator safety.

Rear Guard Protection

Encloses the back area to avoid unauthorized access

The rear door adopts a closed structure design to prevent non-operating personnel from entering the dangerous area.

Left/Right Guard Protection

Side doors isolate moving parts for safety

Fully enclosed design protects operators from accidental contact and external interference.

Emergency Stop

One-press shutdown for emergency response

Stops all operations immediately to prevent equipment damage or injury in case of sudden abnormal situations.

Foot Pedal

Hands-free control improves operating efficiency

Flexible foot pedal control facilitates the operator to complete the bending operation efficiently while ensuring safety.

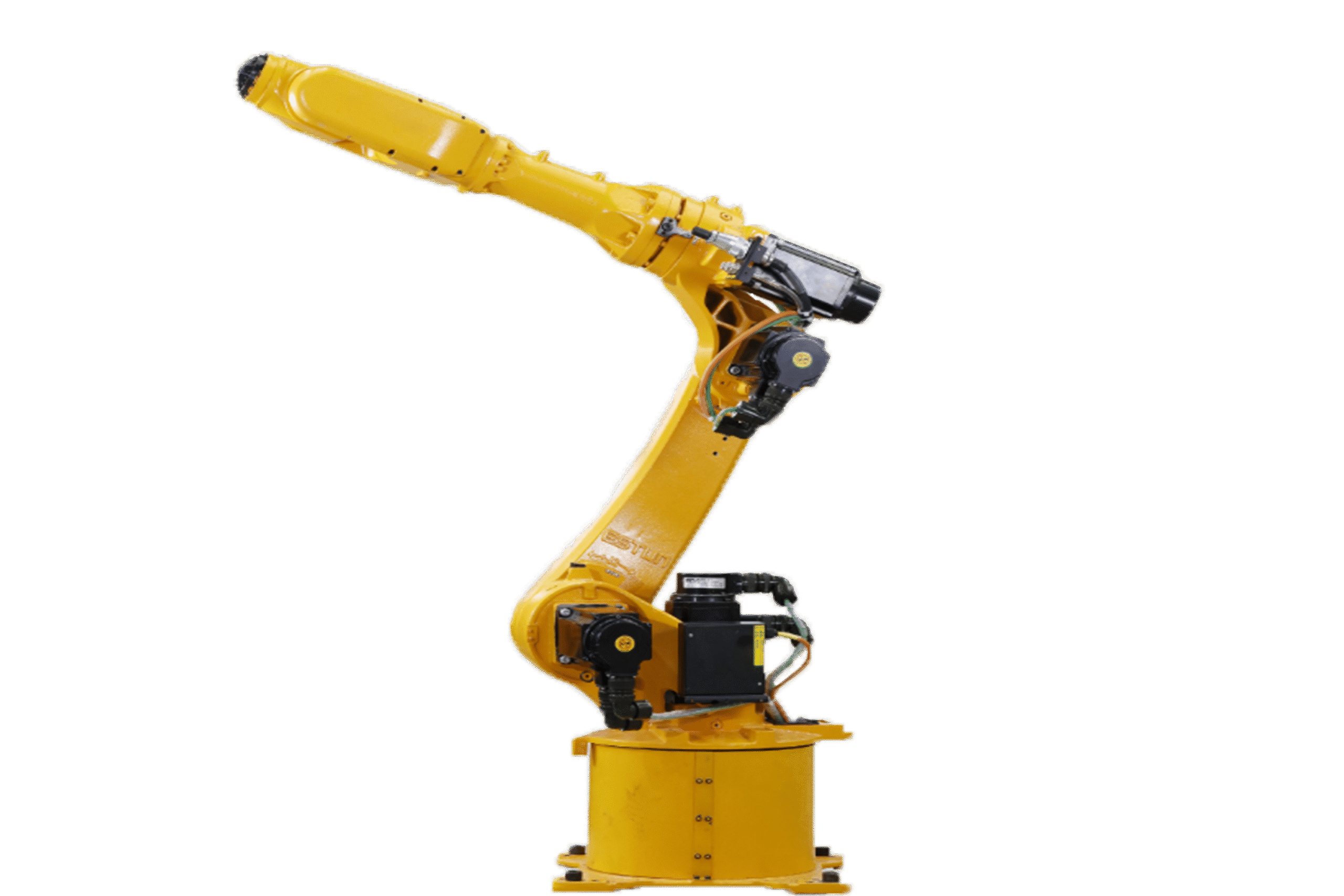

Auxiliary System

The system supports integration of smart auxiliary devices for automated handling and environmental control, enhancing production intelligence.

Bending Robot

Automates loading and bending for smart production

Performs automated loading/unloading and bending tasks to build an efficient, flexible manufacturing line.

Product Technical Specifications

Please check the technical details you require. If necessary, please contact us. Help Center

| Basic Parameters | Bending Capacity (kN) | 150 |

| Bending Length (mm) | 650 | |

| Distance Between Columns (mm) | 300 | |

| Open Height (mm) | 380 | |

| Throat Depth (mm) | 220 | |

| Ram Stroke (mm) | 120 | |

| Main Motor Power (kW) | 2.5 | |

| Overall Dimensionsm L×W×H (mm) | 1450×1400×2050 | |

| Performance | X-Axis Stroke | 400 |

| R-Axis Stroke | 150 | |

| X-Axis Speed (mm/s) | 550 | |

| R-Axis Speed (mm/s) | 200 | |

| Max Fast Approach Speed (mm/s) | 300 | |

| Max Working Speed (mm/s) | 1-30 | |

| Max Return Speed (mm/s) | 300 |

| Basic Parameters | Bending Capacity (kN) | 300 |

| Bending Length (mm) | 1050 | |

| Distance Between Columns (mm) | 800 | |

| Open Height (mm) | 380 | |

| Throat Depth (mm) | 220 | |

| Ram Stroke (mm) | 120 | |

| Main Motor Power (kW) | 2*2.5 | |

| Overall Dimensionsm L×W×H (mm) | 1850×1400×2050 | |

| Performance | X-Axis Stroke | 400 |

| R-Axis Stroke | 150 | |

| X-Axis Speed (mm/s) | 550 | |

| R-Axis Speed (mm/s) | 200 | |

| Max Fast Approach Speed (mm/s) | 300 | |

| Max Working Speed (mm/s) | 1-30 | |

| Max Return Speed (mm/s) | 300 |

| Basic Parameters | Bending Capacity (kN) | 400 |

| Bending Length (mm) | 1500 | |

| Distance Between Columns (mm) | 1200 | |

| Open Height (mm) | 380 | |

| Throat Depth (mm) | 220 | |

| Ram Stroke (mm) | 120 | |

| Main Motor Power (kW) | 2*4 | |

| Overall Dimensionsm L×W×H (mm) | 1850×1400×2050 | |

| Performance | X-Axis Stroke | 400 |

| R-Axis Stroke | 150 | |

| X-Axis Speed (mm/s) | 550 | |

| R-Axis Speed (mm/s) | 200 | |

| Max Fast Approach Speed (mm/s) | 300 | |

| Max Working Speed (mm/s) | 1-30 | |

| Max Return Speed (mm/s) | 300 |

| Basic Parameters | Bending Capacity (kN) | 600 |

| Bending Length (mm) | 1500 | |

| Distance Between Columns (mm) | 1200 | |

| Open Height (mm) | 380 | |

| Throat Depth (mm) | 220 | |

| Ram Stroke (mm) | 120 | |

| Main Motor Power (kW) | 2*5.5 | |

| Overall Dimensionsm L×W×H (mm) | 1850×1400×2150 | |

| Performance | X-Axis Stroke | 400 |

| R-Axis Stroke | 150 | |

| X-Axis Speed (mm/s) | 550 | |

| R-Axis Speed (mm/s) | 200 | |

| Max Fast Approach Speed (mm/s) | 300 | |

| Max Working Speed (mm/s) | 1-30 | |

| Max Return Speed (mm/s) | 300 |

| Basic Parameters | Bending Capacity (kN) | 600 |

| Bending Length (mm) | 2000 | |

| Distance Between Columns (mm) | 1200 | |

| Open Height (mm) | 380 | |

| Throat Depth (mm) | 220 | |

| Ram Stroke (mm) | 120 | |

| Main Motor Power (kW) | 2*5.5 | |

| Overall Dimensionsm L×W×H (mm) | 1850×1400×2150 | |

| Performance | X-Axis Stroke | 400 |

| R-Axis Stroke | 150 | |

| X-Axis Speed (mm/s) | 550 | |

| R-Axis Speed (mm/s) | 200 | |

| Max Fast Approach Speed (mm/s) | 300 | |

| Max Working Speed (mm/s) | 1-30 | |

| Max Return Speed (mm/s) | 300 |

Get in Touch with Us Now!

Please fill in the form and describe your requirements. Our team will get back to you within 24 hours.