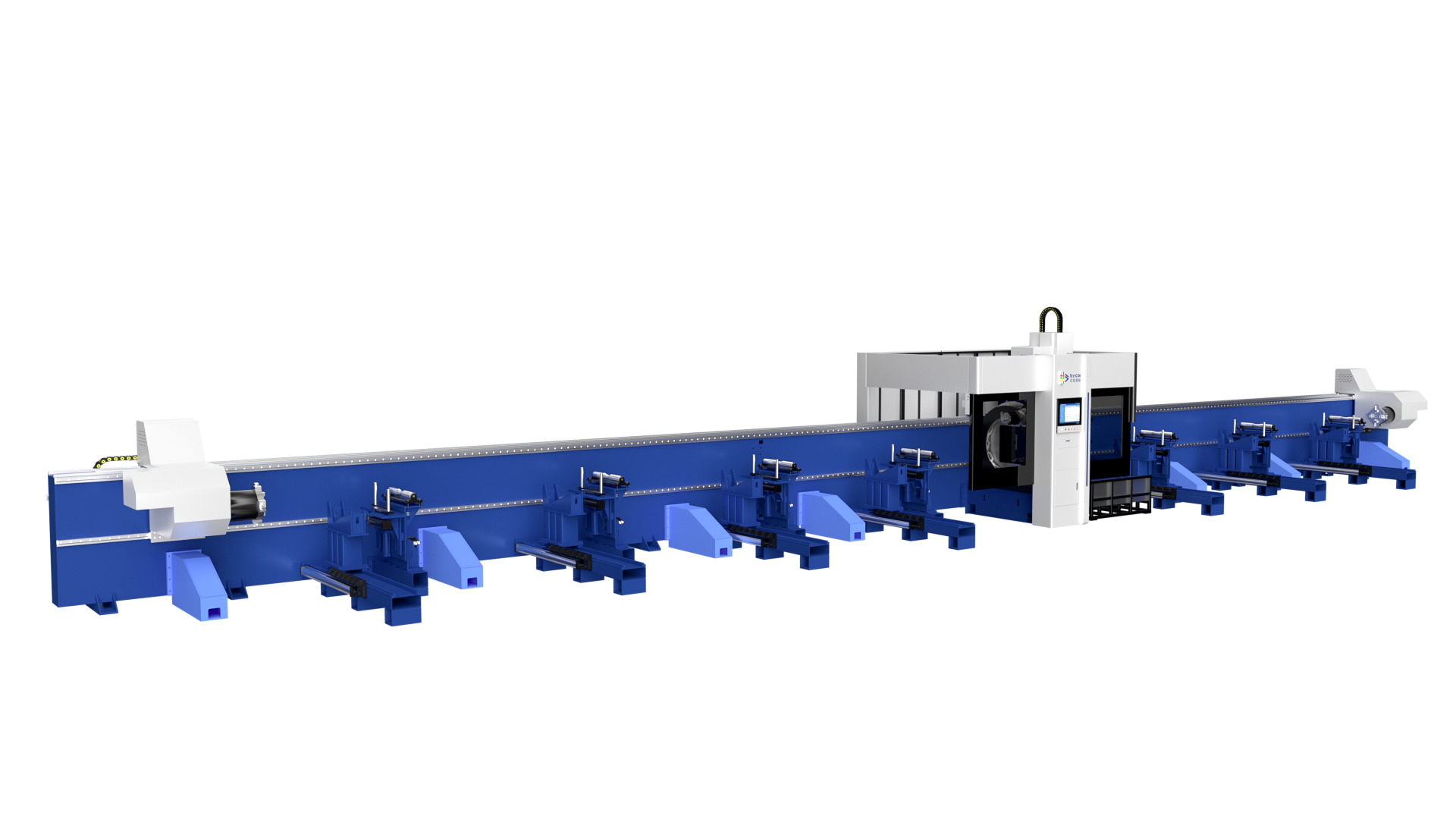

BLT3 Series 3 Chuck Tube Laser Cutting Machine

Opt for the Tube Laser Cutter for seamless processing. Its unique three-chuck design ensures precise rotation and stable support, significantly enhancing tube cutting efficiency and accuracy.

Mechanical System

The robust structure offers excellent load-bearing capacity, ensuring stability and precision even during high-speed operations.

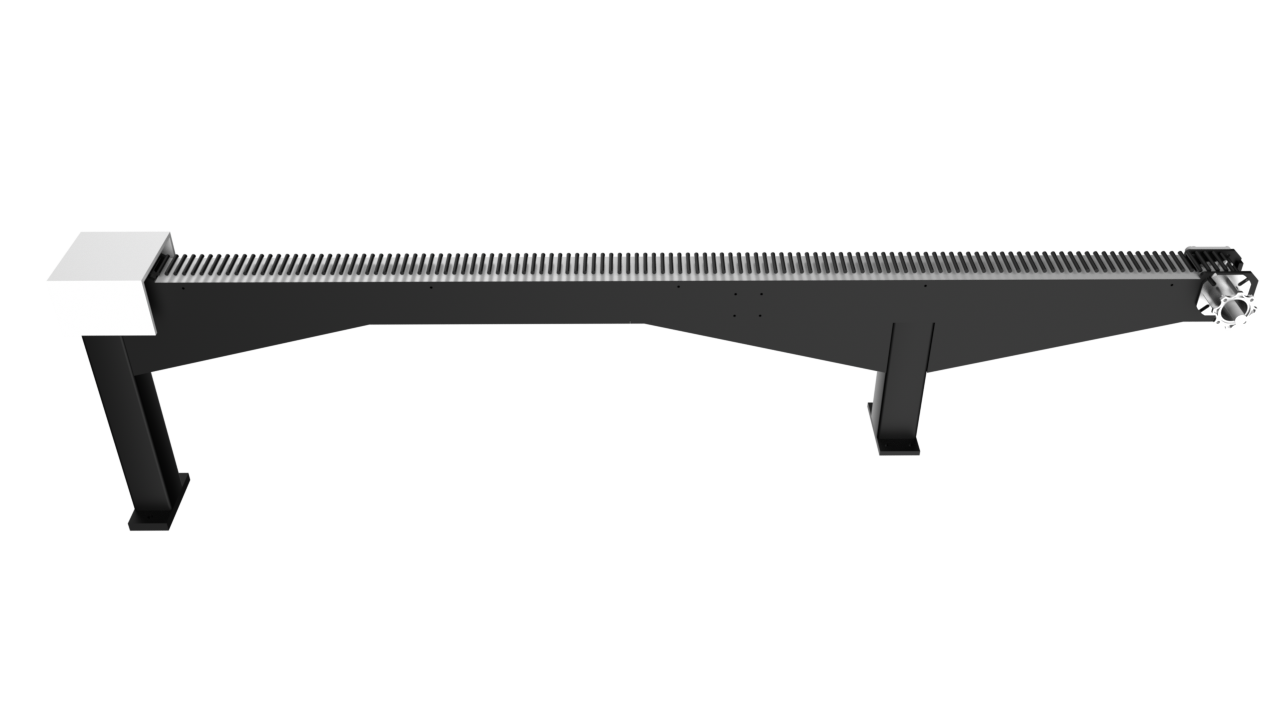

BED

High-strength structure to ensure machine stability

The bed adopts a reinforced structure to reduce vibration, improving cutting accuracy and machine lifespan.

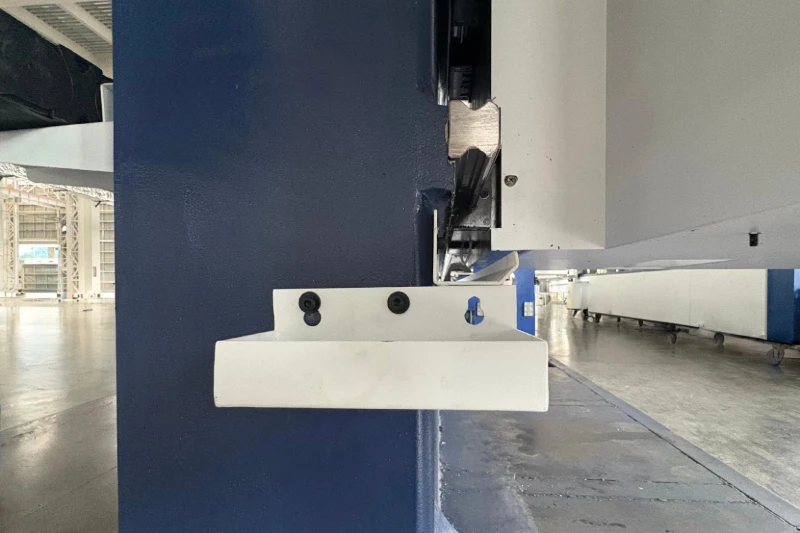

Chuck

Precise clamping to enhance machining stability

The chuck firmly secures the tube to prevent rotational deviation, ensuring overall processing effect.

Chuck Number

Multi-chuck design for versatile applications

A multi-chuck design accommodates various tube lengths and diameters, expanding processing versatility.

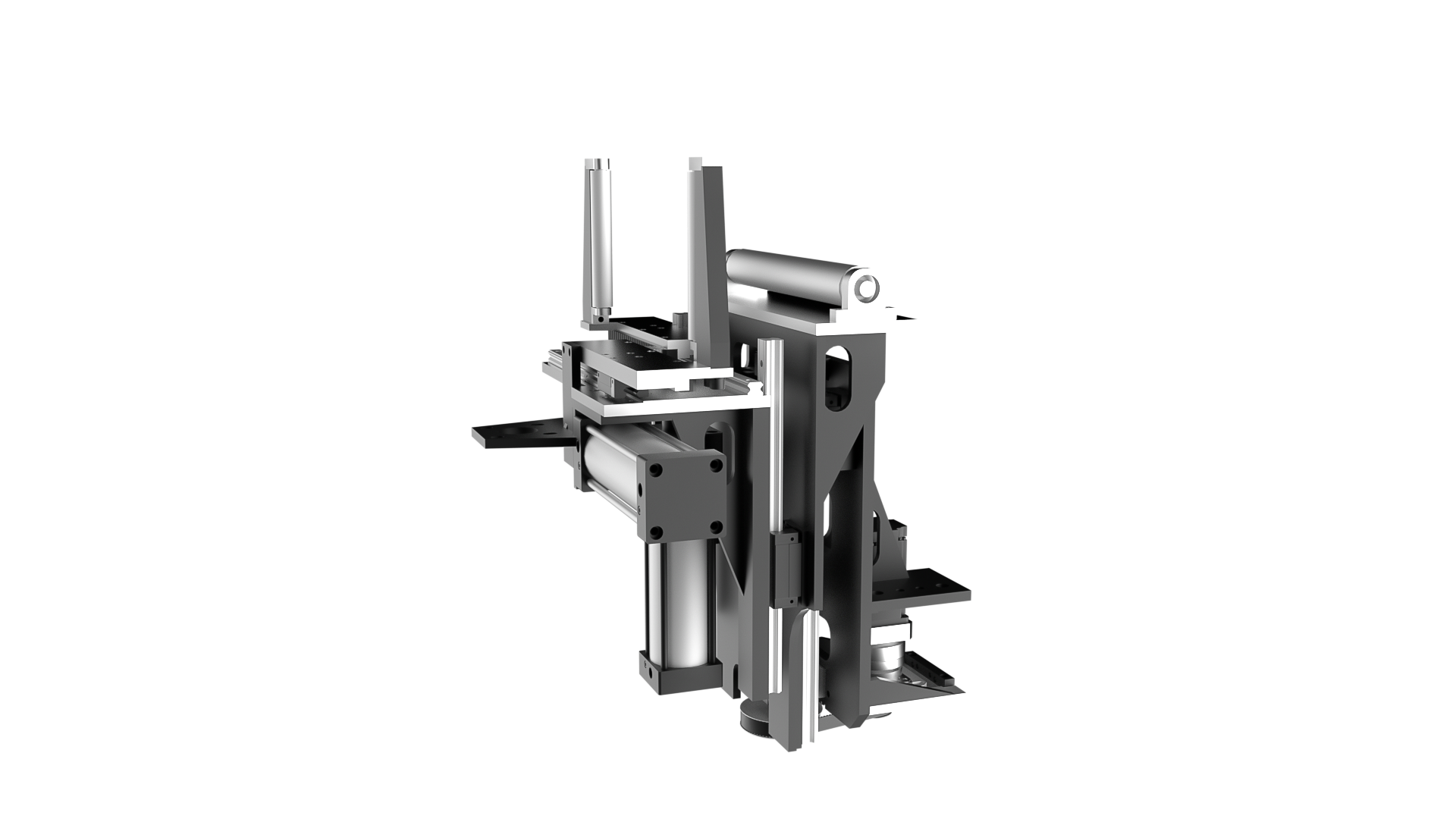

Servo Support Roller

Dynamic support to prevent tube sagging

The servo roller intelligently adjusts to support tubes, preventing sagging and ensuring cutting accuracy for long tubes.

Servo Unloading Rack

Automatic receiving for higher production efficiency

The servo unloading rack automatically receives finished parts, reducing manual intervention and boosting productivity.

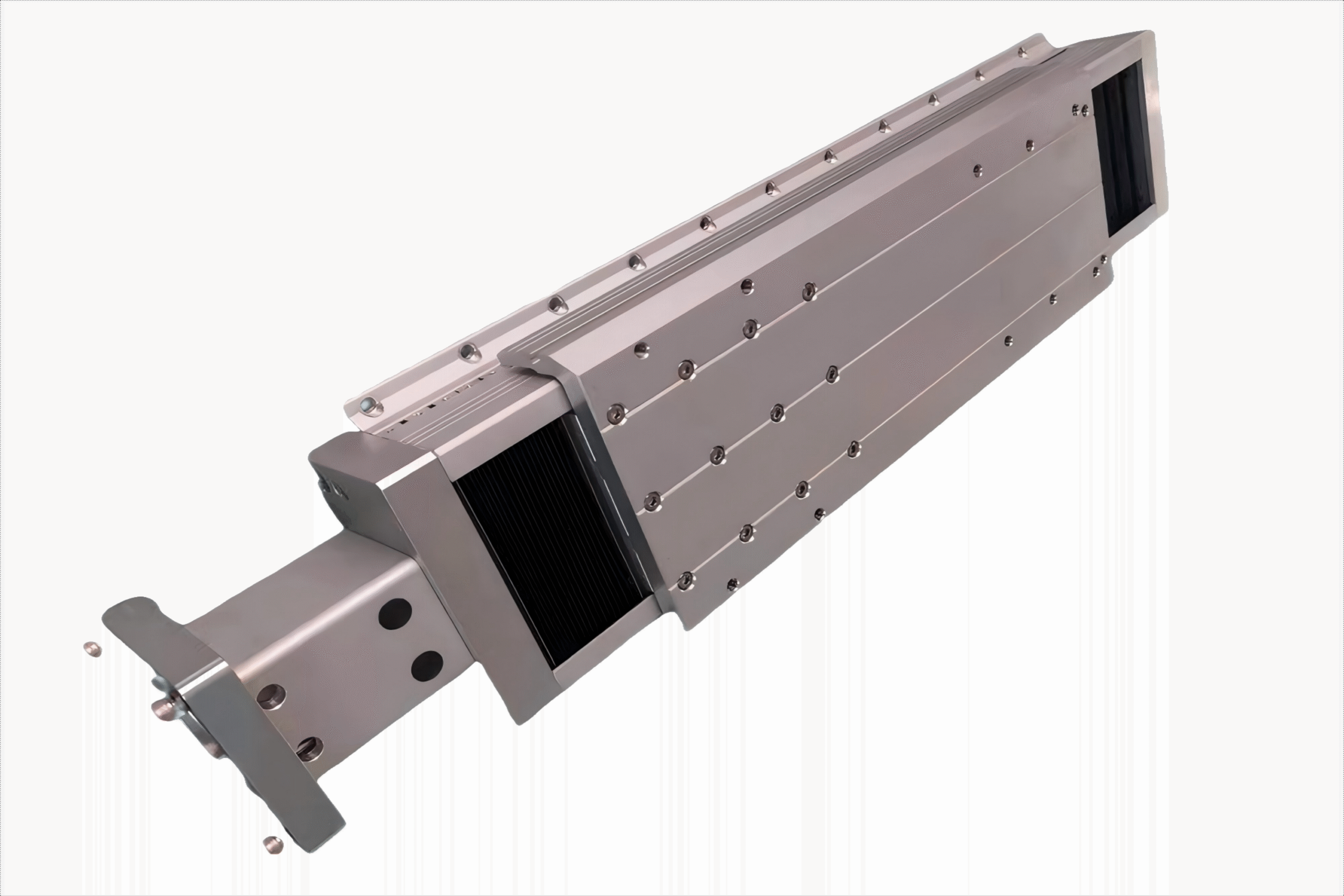

Z-axis Slide Module

High-precision dynamic focusing ensures cutting quality

With a high-rigidity structure and precision servo drive, it maintains optimal focus stability during high-speed movement, seamlessly adapting to different material thicknesses.

Motion System

Quick response and precise positioning enable fast, efficient, and smooth cutting operations.

Servo Motor and Drive

High-response control for precise precision

The high-response servo system ensures precise control, maintaining cutting accuracy even at high speeds.

Gear Reducer

Stable transmission for stronger power output

The gear reducer delivers smooth power transmission, ensuring stable machine operation and sufficient torque output.

Guide Rail

Precision guiding to maintain smooth motion

High-precision guide rails reduce friction and deviation, ensuring smooth movement and extending machine life.

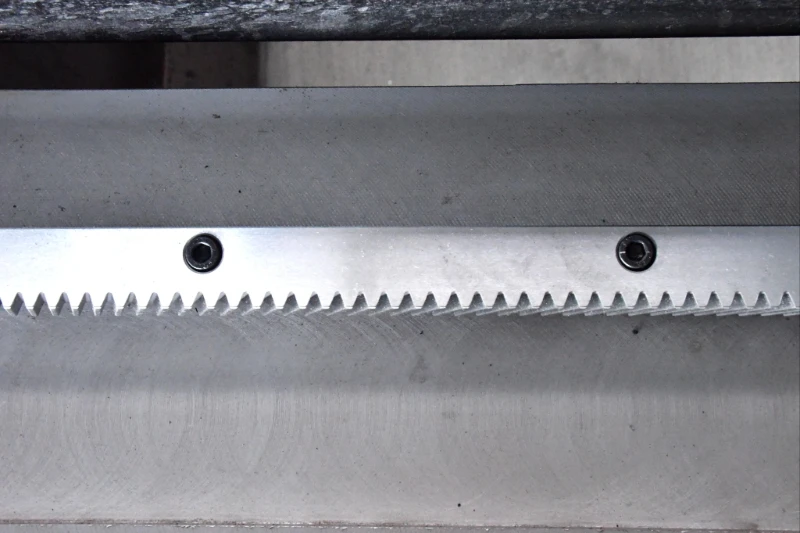

Rack

Efficient transmission for better positioning accuracy

Rack transmission provides high-speed response, enhancing positioning accuracy and processing efficiency.

Cable Carrier

Cable management to reduce wear risk

The cable carrier neatly organizes cables and hoses, preventing bending and wear, ensuring stable system operation.

Optical System

The stable laser output delivers fine, clean cutting lines, resulting in superior processing quality.

Laser Source

Stable laser source for excellent quality

The laser source delivers a stable, high-energy beam for fast cutting with superior edge quality.

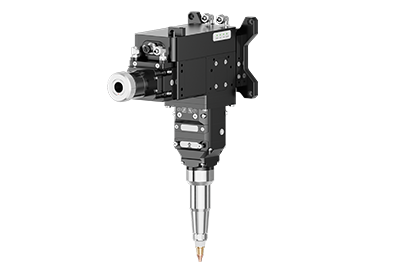

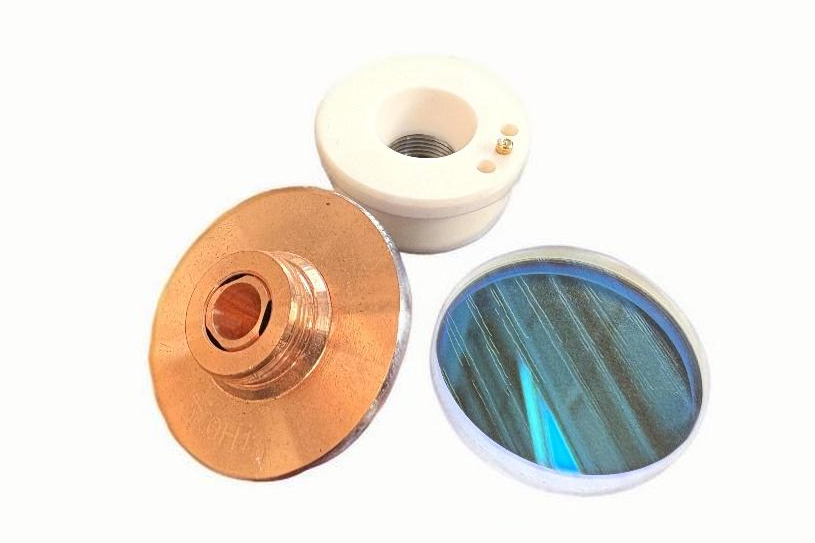

Laser Cutting Head

Intelligent focusing adapting to various materials

The cutting head features smart focusing to handle various materials and thicknesses with ease.

Control System

The user-friendly interface and seamless workflows significantly boost production efficiency.

Bus Controller

Centralized control for higher response efficiency

The bus controller integrates multiple control modules, improving data transmission speed and response efficiency.

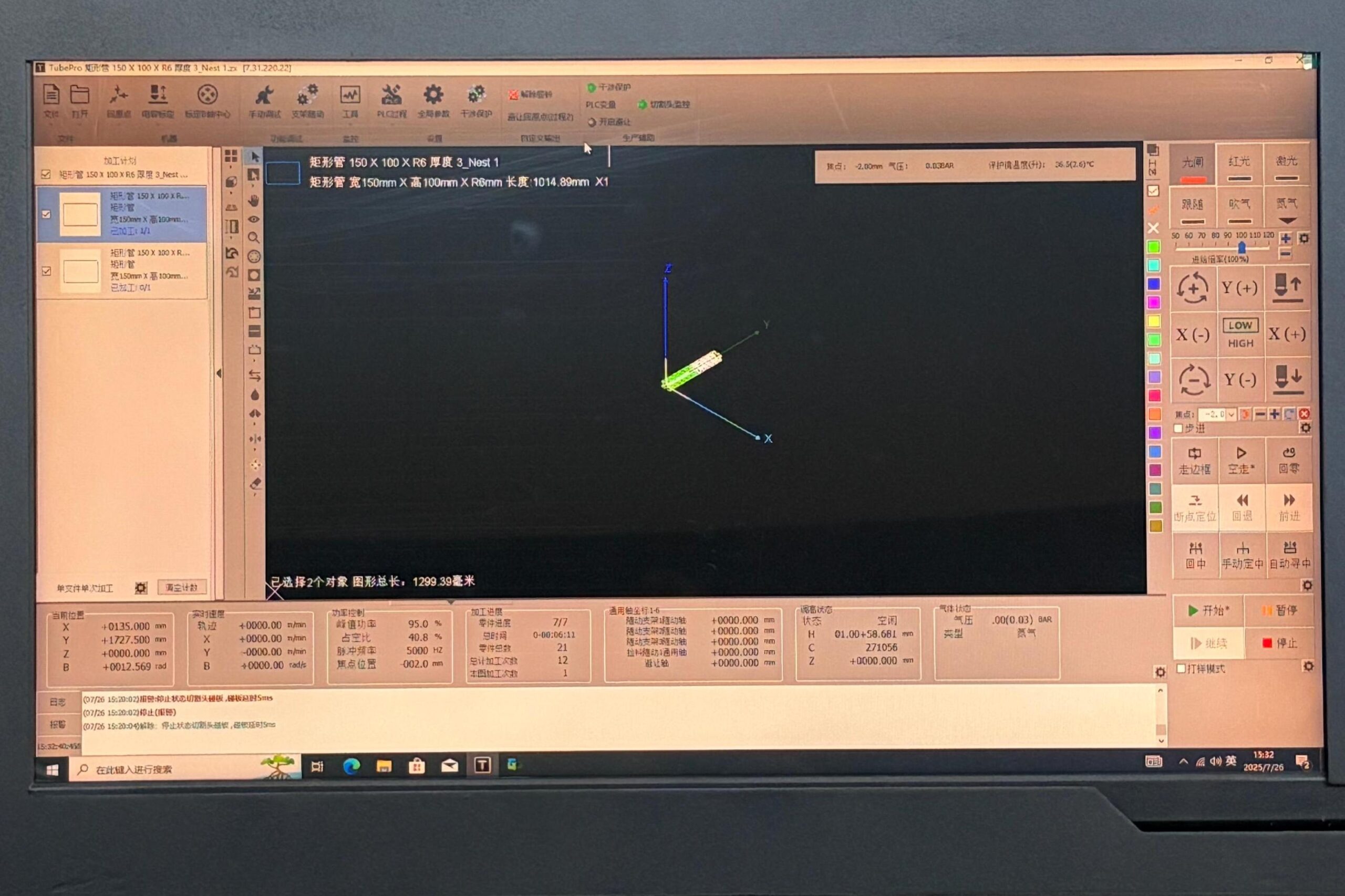

Operating Software

User-friendly interface for easy operation

The software is intuitive and easy to use, helping users quickly master operations and improve efficiency.

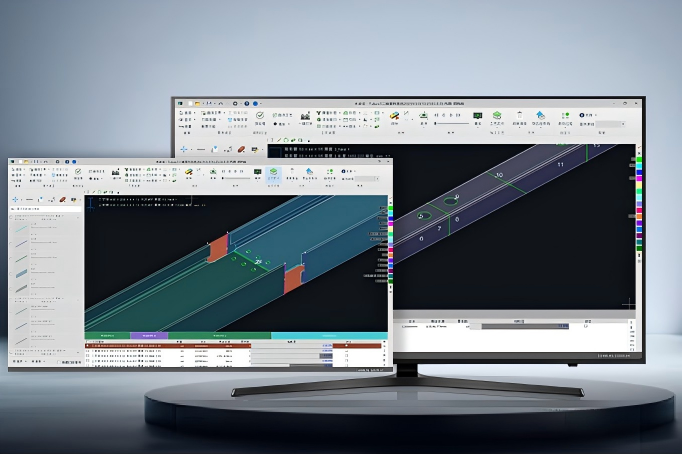

Nesting Software

Optimized layout for material cost savings

The nesting software uses intelligent algorithms to optimize layouts, maximizing material usage and reducing costs.

Electrical System

Well-organized design ensures reliable operation, reducing malfunctions and enhancing overall stability.

Electrical

Rational layout maintains circuit reliability

The electrical is responsible for providing stable power supply to all components, and coordinates the signal transmission and safety protection of each part.

Voltage Stabilizer

Stable voltage to protect equipment

The voltage stabilizer maintains constant voltage to protect sensitive components and ensure safe operation.

Industrial PC

High-speed computing for complex tasks

The industrial PC offers powerful performance, quickly handling complex graphics and data processing tasks.

Display

High-definition display for easier monitoring

The high-definition display provides clear visuals for easy operation monitoring during cutting processes.

Remote Controller

Flexible operation for enhanced convenience

The wireless remote controller allows operators to control the machine remotely, enhancing operational flexibility.

Cooling System

Efficient heat dissipation prevents overheating, ensuring continuous and stable operation.

Water Chiller

Efficient cooling to protect key components

The efficient water chiller provides stable cooling for core components like the laser source, preventing overheating.

Cabinet Heat Exchanger

Optional

Precise temperature control for longer lifespan

The heat exchanger precisely regulates cabinet temperature, protecting electronic components for stable operation.

Gas Supply System

Precise air pressure control produces smoother cutting edges and enhances processing results.

Pneumatic Valve Block

Precise control for cutting quality assurance

The pneumatic valve block precisely controls gas flows, ensuring cutting quality and efficiency.

Pressure Alarm

Real-time monitoring for operational safety

The pressure alarm monitors abnormal pressure in real time, providing timely warnings for safe operation.

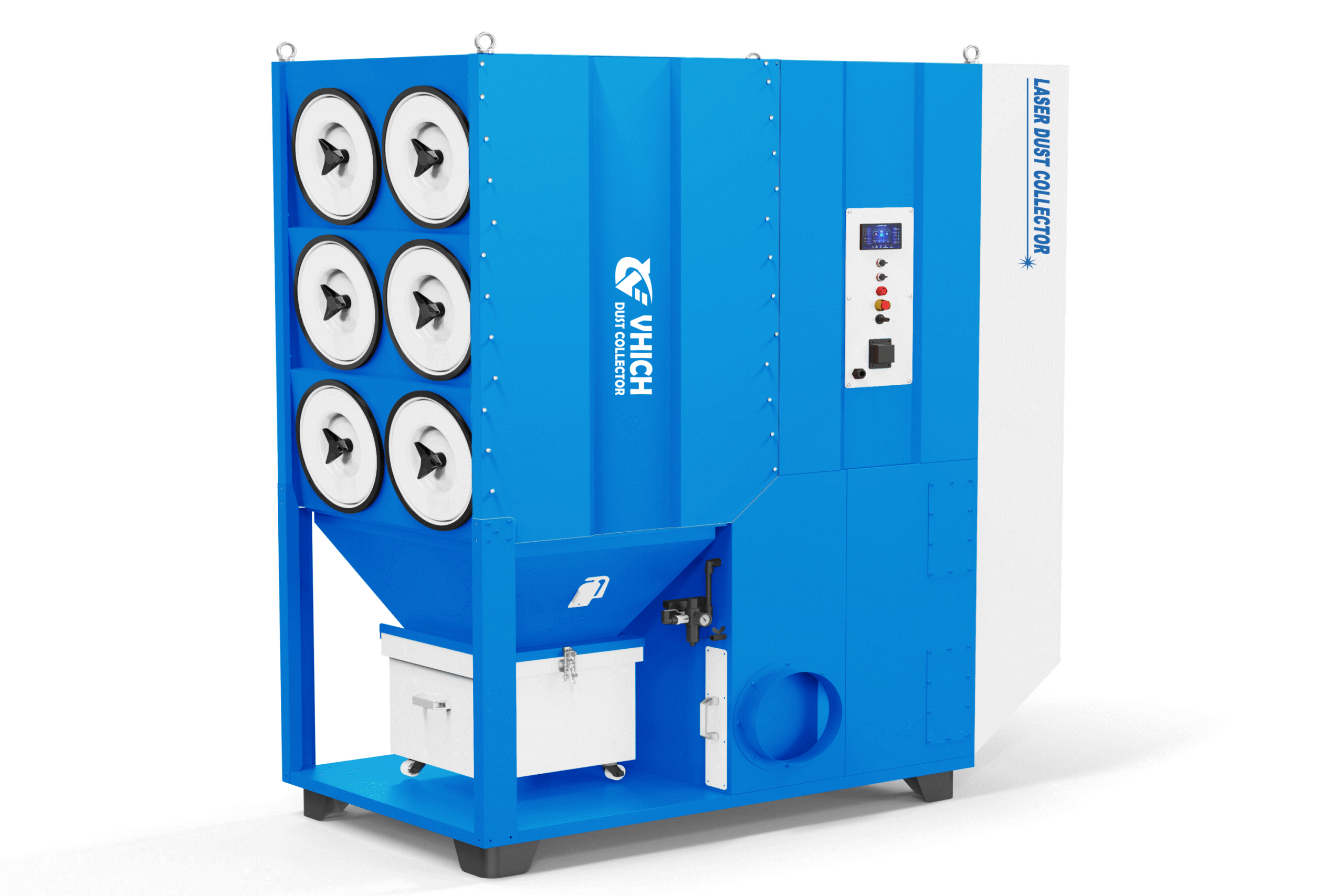

Dust Extraction System

Effective dust removal keeps the workspace clean and prolongs the machine’s lifespan.

Dust Removal Structure

Efficient dust removal for a clean environment

The optimized dust removal structure swiftly evacuates fumes, keeping the cutting area clean and visible.

Centrifugal Fan

Powerful exhaust for better dust removal

The centrifugal fan delivers strong airflow, increasing exhaust speed and efficiency for dust removal.

Safety System

Multiple protective measures reduce risks and create a safer working environment.

Emergency Stop

Quick shutdown for personnel safety

The emergency stop quickly cuts power, ensuring operator safety in emergency situations.

Lubrication System

Precise automatic lubrication reduces wear, lowers maintenance costs, and extends service life.

Lubricating Oil Pump

Automatic lubrication to reduce maintenance costs

The automatic lubrication system delivers oil regularly, reducing manual maintenance and costs.

Oil Collection Device

Effective oil recovery for eco-friendly and no leakage

The oil collection device efficiently recovers excess oil, preventing leaks and promoting environmental protection.

Wear Parts

Made of wear-resistant materials, these parts are easy to replace, minimizing production downtime.

Wear Parts Kit

Complete kit ensuring equipment operation

The included wear parts kit allows timely replacements, reducing downtime and ensuring production efficiency.

Optional Accessories

The variety of accessories can be flexibly configured to meet diverse processing needs and increase the machine’s value.

Air Compressor

Continuous air supply for process requirements

The air compressor delivers a steady air supply, meeting continuous pressure requirements for cutting processes.

Semi-Automatic Loading System

Simplified loading enhancing operational efficiency

The semi-automatic loading system reduces manual handling, improving loading speed and efficiency.

fully-Automatic Loading System

Fully automatic operation saving labor costs

The automatic loading system enables automated tube sorting and feeding, supporting intelligent manufacturing.

Product Technical Specifications

Please check the technical details you require. If necessary, please contact us. Help Center

| Basic Parameters | Max Tube Length (mm) | 9000 |

| Tube Size Range (mm) | ◯ 10 ~350mm ▢ 10~350mm |

|

| Max Single Tube Weight (kg) | 900 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 36000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 80 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

| Basic Parameters | Max Tube Length (mm) | 9000 |

| Tube Size Range (mm) | ◯ 25 ~520mm ▢ 25~520mm |

|

| Max Single Tube Weight (kg) | 1500 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 36000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 60 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

| Basic Parameters | Max Tube Length (mm) | 9000 |

| Tube Size Range (mm) | ◯ 80 ~640mm ▢ 80~640mm |

|

| Max Single Tube Weight (kg) | 1800 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 36000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 40 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

| Basic Parameters | Max Tube Length (mm) | 12000mm |

| Tube Size Range (mm) | ◯ 10 ~350mm ▢ 10~350mm |

|

| Max Single Tube Weight (kg) | 1200 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 46000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 80 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

| Basic Parameters | Max Tube Length (mm) | 12000mm |

| Tube Size Range (mm) | ◯ 25 ~520mm ▢ 25~520mm |

|

| Max Single Tube Weight (kg) | 2000 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 46000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 60 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

| Basic Parameters | Max Tube Length (mm) | 12000mm |

| Tube Size Range (mm) | ◯ 80 ~640mm ▢ 80~640mm |

|

| Max Single Tube Weight (kg) | 2500 | |

| Shortest Remnant Length (mm) | No waste materials | |

| Overall Dimensions (mm) | 46000*2100*3000 | |

| Performance | Max Speed of Laser Head (m/min) | 100 |

| Max Acceleration of Laser Head (m/s²) | 0.8G | |

| Max Rotational Speed of Chuck (r/min) | 160 | |

| Max Speed of Chuck Feed Shaft (m/min) | 40 | |

| Max Acceleration of Chuck Feed shaft (m/s²) | 1.0G | |

| Positioning Accuracy (mm) | ±0.05 | |

| Repositioning Accuracy (mm) | ±0.02 |

Get in Touch with Us Now!

Please fill in the form and describe your requirements. Our team will get back to you within 24 hours.