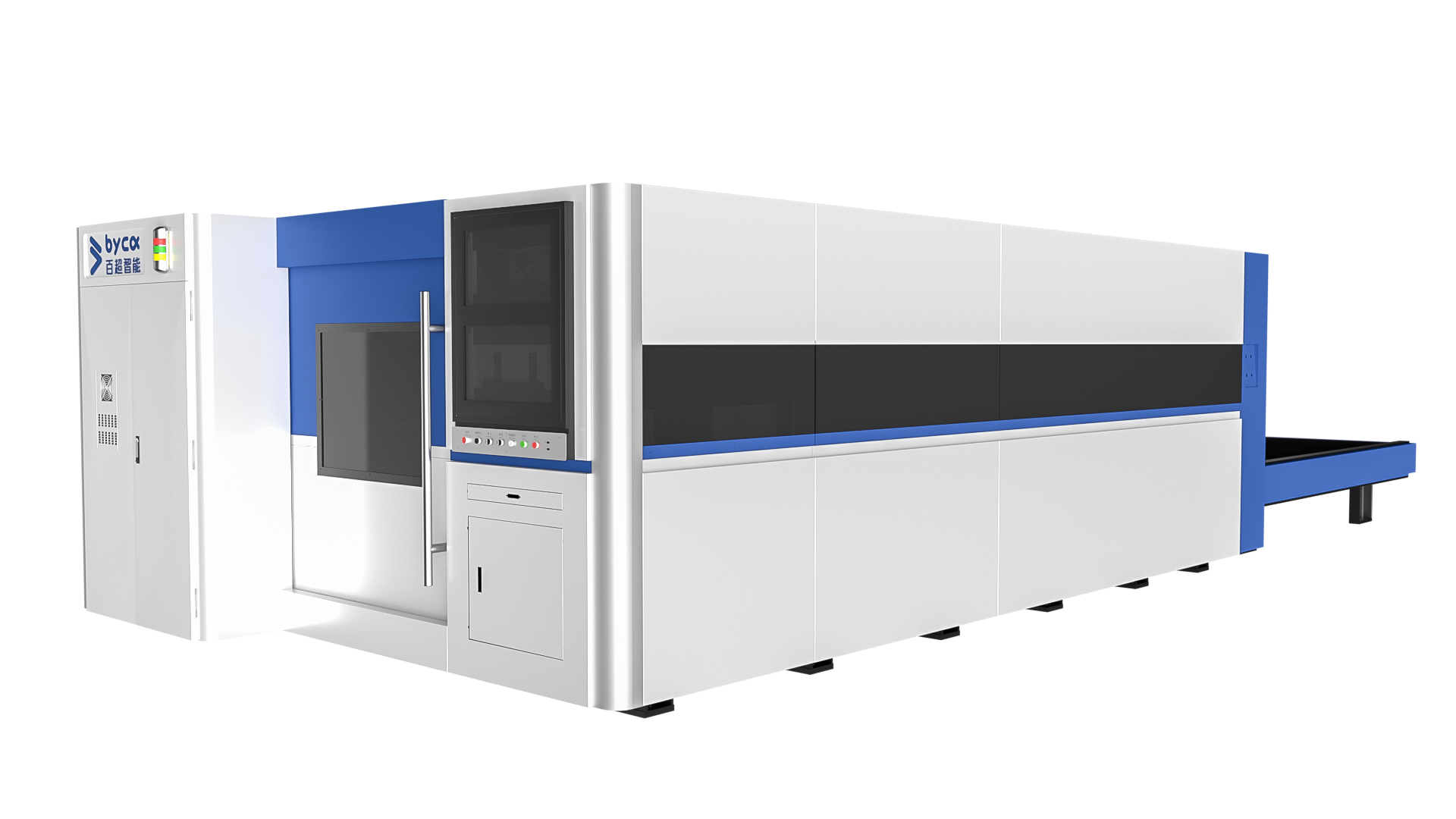

BLSF Series Enclosed Double Table Sheet Laser Cutting Machine

The “double table” and “fully enclosed” are ideal choices for sheet metal processing workshops that pursue high efficiency, high safety and stable continuous production.

Mechanical System

High-strength structural support that delivers both precision and lasting stability.

BED

High rigidity structure achieves stable, deformation-free body

The integrated steel plate welded bed, after aging treatment, has strong anti-deformation ability, ensuring stable support under high-power cutting and long-term load.

Beam

Lightweight aluminum alloy enables high-speed motion without vibration

The crossbeam is made of aluminum alloy, featuring light weight and high strength. Combined with the drive system and guide rails, it effectively reduces the running inertia and ensures smooth operation at high speeds.

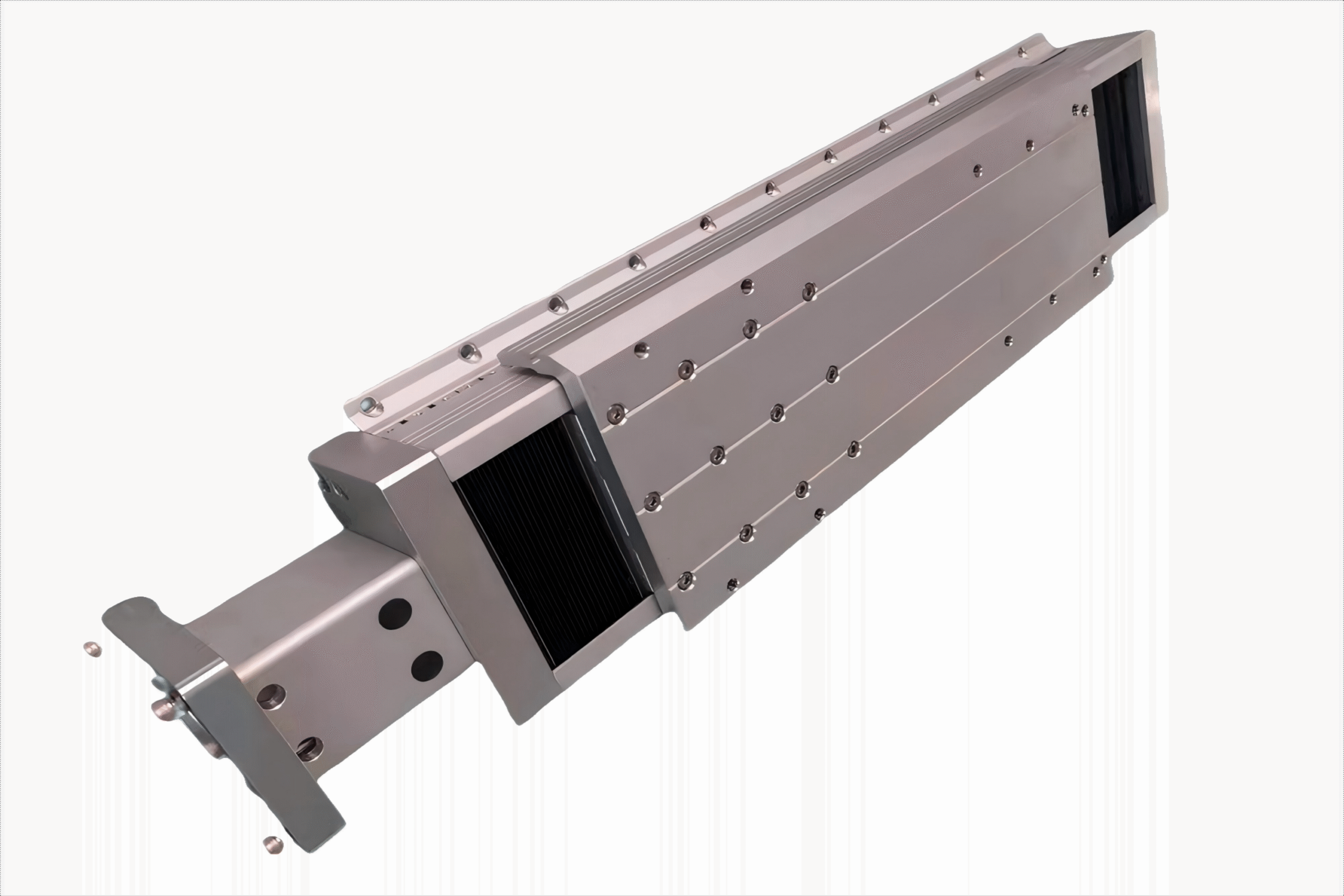

Z-axis Slide Module

High-precision dynamic focusing ensures cutting quality

With a high-rigidity structure and precision servo drive, it maintains optimal focus stability during high-speed movement, seamlessly adapting to different material thicknesses.

Exchange Table

Optional

Dual workstations switch for enhanced work efficiency

The exchange mechanism adopts a chain synchronous drive system, enabling cutting and loading/unloading to be carried out simultaneously, significantly reducing the downtime waiting time and enhancing the production rhythm.

Cover

Fully enclosed design ensures safety and eco-friendliness

The fully enclosed design blocks the leakage of laser radiation and smoke dust, effectively protecting the safety of operators. The transparent observation window is convenient for monitoring the cutting process.

Motion System

Key moving parts coordinate smoothly ensuring rapid response and precise dynamic performance.

Servo Motor and Drive

Fine control with fast, responsive performance

The servo system is used to precisely control the position, speed and acceleration of the motion axis, achieving stable and reliable dynamic response and repeatability accuracy.

Gear Reducer

High torque output for smooth and reliable operation

The gear reducer is used to reduce the high-speed rotation of the servo motor into low-speed, high-torque output suitable for cutting, ensuring smooth and precise transmission.

Guide Rail

Precision guide rails ensure smooth, natural motion

High-precision guide rails reduce mechanical friction and wear, extend equipment lifespan, and maintain stability and accuracy during long-term processing.

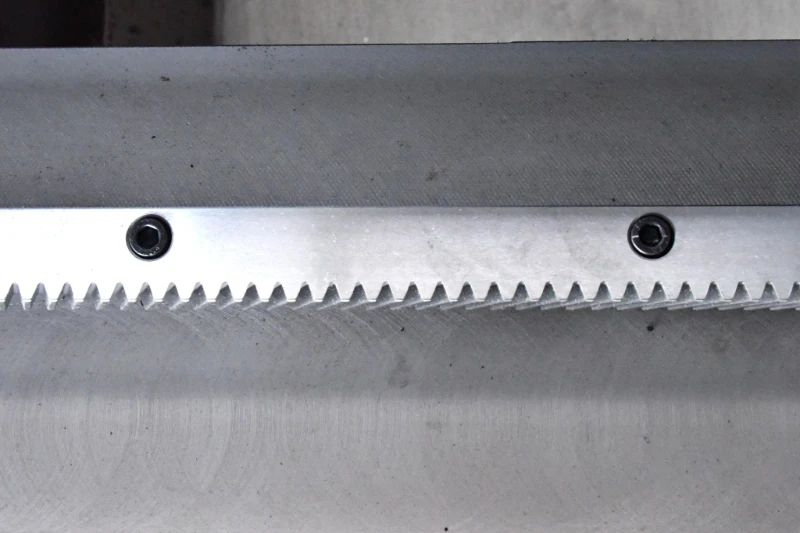

Rack

Accurate power transmission with superior efficiency

The rack with the gear to convert the motor’s rotary motion into linear movement of the cutting head or worktable, achieving fast and precise positioning.

Bellow Cover

Dust-proof design extends machinery lifespan

The bellow cover is used to protect moving parts such as guide rails and ball screws, preventing dust, metal debris, and laser fumes from entering and extending the machine’s service life.

Cable Carrier

Cable management reduces wear and break risks

The cable carrier is used to guide and protect cables, air pipes, and water hoses, preventing them from tangling, breaking, or wearing out during the movement of the laser cutter.

Optical System

Efficient transmission with precise focusing enhances cutting results and energy utilization.

Laser Source

Powerful energy output increases cutting speed

The laser is used to generate high-energy and high-density laser beams to melt or vaporize metals. Lasers of different powers and types can meet the processing requirements of materials and thicknesses.

Laser Cutting Head

Precise focusing maintains consistent cutting quality

The cutting head is used to focus the laser beam and precisely project it onto the material surface. It is usually equipped with an automatic focusing system and a nozzle design to adapt to different materials and thicknesses, ensuring cutting quality.

Control System

Fast response and stable operation guarantee efficient and accurate processing.

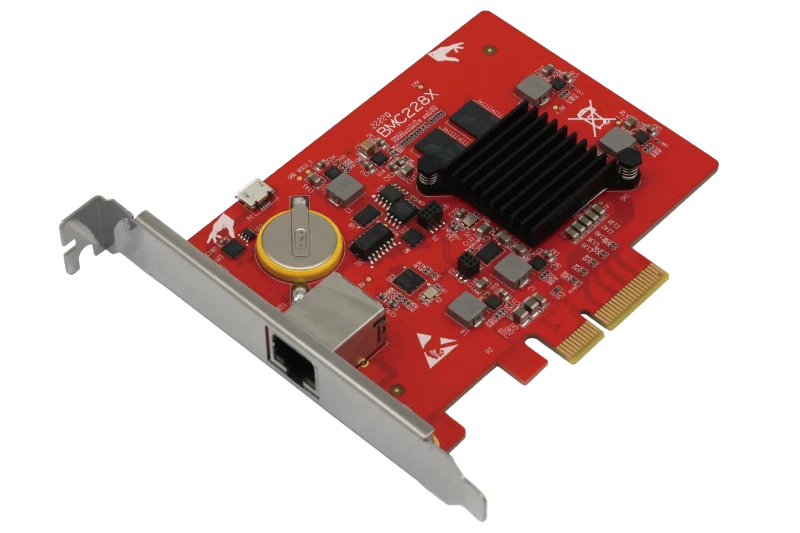

Bus Controller

Fast data transfer supports stable system operation

The cutting bus system is responsible for connecting various electronic modules, achieving efficient synchronization of data transmission and command control, and enhancing the automation level of the equipment.

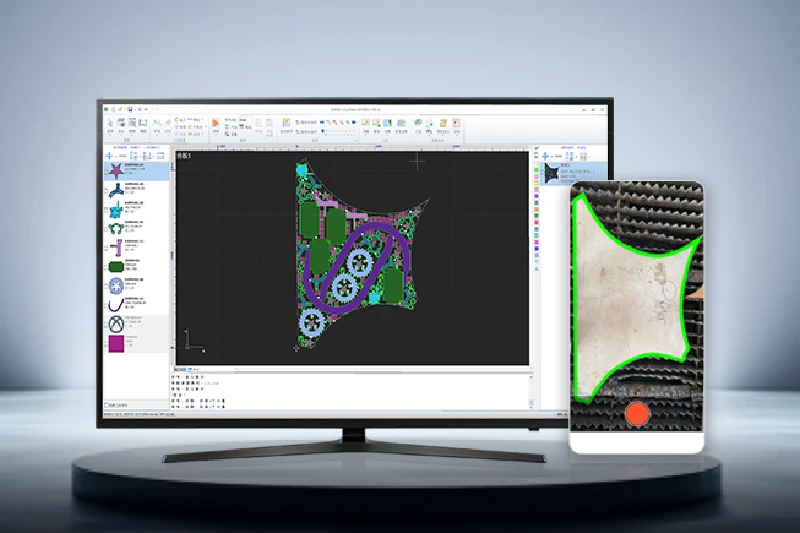

Operating Software

Intuitive interface for easy, efficient operation

The operation software is used to design the cutting path, control the operation of the equipment and achieve automated processing. It supports switching between multiple languages and offers a user-friendly interface.

Nesting Software

Optimizes layout, saves material and reduces cost

Nesting software is used to optimize material utilization. By intelligently arranging cutting patterns, it reduces waste. It supports a variety of sheet sizes and shapes, helping enterprises achieve their cost savings goals.

Electrical System

Scientific circuit layout ensures safe and reliable equipment operation.

Electrical

Rational layout maintains circuit reliability

The electrical is responsible for providing stable power supply to all components. It includes the control cabinet, switching power supply, terminal blocks, etc., and coordinates the signal transmission and safety protection of each part.

Voltage Stabilizer

Stable voltage protects equipment for safe work

The voltage regulator provides a stable voltage for the laser cutter, preventing grid fluctuations from affecting the normal operation of the equipment.

Industrial PC

Powerful performance continually supports industry

The industrial control computer is responsible for running the operation software and processing complex data calculations to ensure that the equipment can work continuously for a long time.

Display

Clear display enables easy monitoring and management

The display shows the operation interface, processing parameters and running status of the machine in real time, which is convenient for the operator to monitor and adjust.

Remote Controller

Wireless control enhances flexible and convenience

The remote controller is used for operating the machine from a distance, making it convenient for operators to perform positioning, debugging, and basic control.

Cooling System

Efficient cooling system prolongs equipment lifespan and maintains stable performance.

water Chiller

Efficient cooling maintains stable laser output

The water chiller provides circulating cooling for the laser and key components, keeping the equipment operating within a safe temperature range and preventing damage caused by overheating.

Cabinet Heat Exchanger

Optional

Effective heat dissipation prolongs control system life

The heat exchanger cools the interior of the electrical cabinet, maintaining a clean and constant temperature environment inside the cabinet, and enhancing the reliability and service life of the equipment.

Gas Supply System

Continuous and stable airflow ensures safe and efficient equipment operation.

Pneumatic Valve Block

Precise airflow control boosts equipment efficiency

The pneumatic valve block controls the switching of different gases, regulates flow and stabilizes pressure, ensuring a smooth cutting process and improve cutting quality and reduce gas consumption costs.

Pressure Alarm

Real-time pressure monitoring enhances safety

The gas pressure alarm monitors the pressure in real time. When the pressure is abnormal, it will issue an alarm promptly to prevent processing malfunctions and ensure the safety of cutting.

Dust Extraction System

Effective dust extraction system maintains a clean environment and smooth equipment operation.

Zoned Dust Removal Structure

Zoned dust extraction keeps work area clean

The cutting area is divided into multiple zones, and the dust removal system of the corresponding zone is precisely activated based on the position of the cutting head. This design effectively mitigates dust.

Centrifugal Fan

Optional

Powerful fan ensures efficient system ventilation

Centrifugal fans efficiently remove the dust and waste gas generated during cutting. It features large airflow, strong pressure and stable operation, which helps to keep the working environment clean.

Safety System

Multiple safety protections effectively prevent accidents.

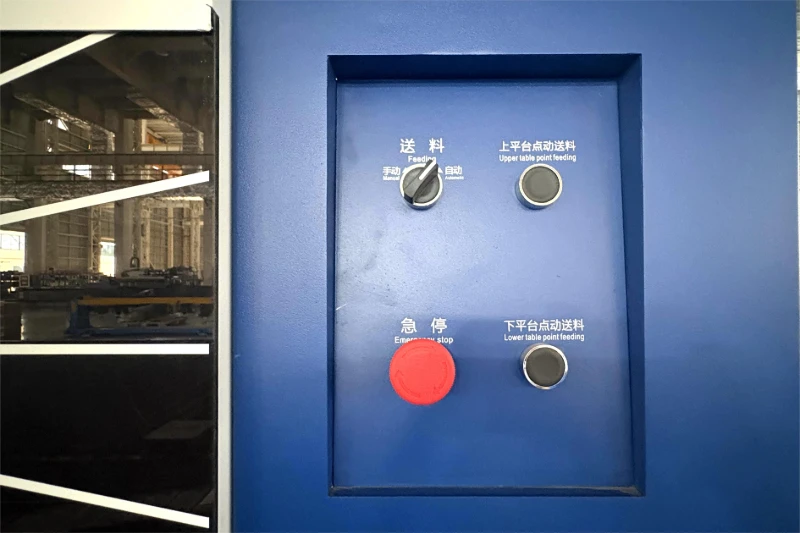

Emergency Stop Button

Quick power cut-off protects personnel and equipment

The emergency stop switch is an important safety protection device, used to immediately cut off the power supply in an emergency to ensure the safety of operators and equipment.

Video recording equipment

Real-time recording facilitates monitoring and playback

The video recording equipment records the laser cutting process in real time, facilitating operation monitoring and quality traceability. It helps technicians analyze the cutting effect and the causes of faults.

Camera

HD video monitoring ensures production safety

The camera capture the real-time working status of the machine and the cutting details, helping the operator monitor the processing procedure, enhancing the safety of equipment management.

Safety Light Curtain

Light curtain sensing prevents accidental injuries

The light curtain protection prevents personnel from mistakenly entering the cutting area and causing injury. When someone passes through the light curtain, the system will automatically stop the machine.

Lubricating System

Continuous lubrication reduces wear and extends equipment life cycle.

Lubricating Oil Pump

Continuous lubrication reduces mechanical wear

The lubricating oil pump delivers lubricating oil to the moving mechanical parts, reducing friction and wear. It ensures smooth operation of the machine and reduces maintenance costs.

Oil Collection Device

Efficiently collects oil to keep equipment clean

The oil collection device recycles used lubricating oil to prevent the oil from polluting the environment. It helps keep the interior of the equipment clean and extend the service life of its components.

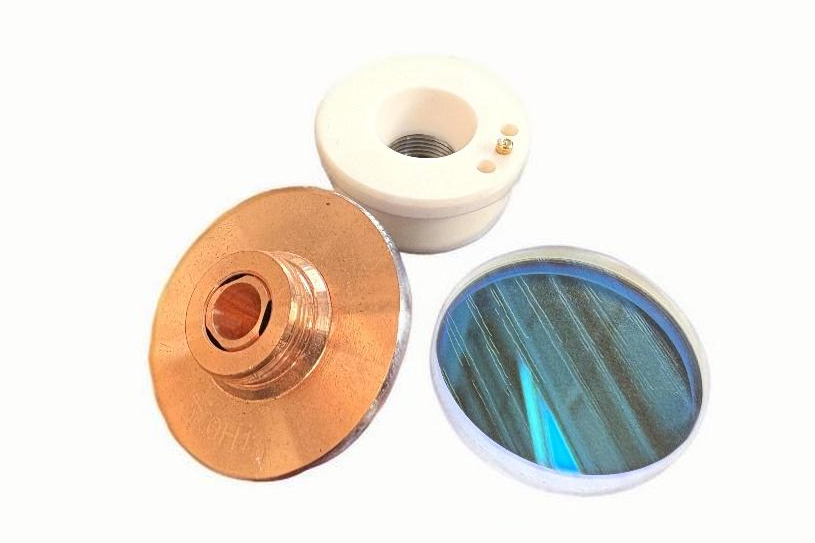

Wear Parts

Wear-resistant and high-temperature resistant ensure stable operation and reduce maintenance burden.

Wear Parts Kit

Complete parts for easy and quick replacement

The wear parts kit includes commonly components, such as nozzles, protective lenses, and ceramic rings, facilitating timely replacement. It helps ensure the continuity of production.

Optional Accessories

Diverse configuration options meet various needs and enhance equipment capabilities.

Air Compressor

Continuous air supply ensures stable equipment operation

The air compressor provides stable compressed air for the laser cutter, supporting gas injection and blow-off during the cutting process.It ensures a clean gas environment around the cutting head, helping to improve cutting quality.

Product Technical Specifications

Please check the technical details you require. If necessary, please contact us. Help Center

| Basic Parameters | Working Area (mm) | 3000*1500 |

| Table Load Bearing (kg) | 2000 | |

| Overall Dimensions (mm) | Main Frame: 5170*2900*2190 Tail Frame: 3440*2260*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 1520 | |

| Y Axis Travel (mm) | 3050 | |

| Z Axis Travel (mm) | 140/300 | |

| X, Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X, Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 4000*1500 |

| Table Load Bearing (kg) | 2500 | |

| Overall Dimensions (mm) | Main Frame:6300*2900*2190 Tail Frame:4380*2260*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 1520 | |

| Y Axis Travel (mm) | 4050 | |

| Z Axis Travel (mm) | 140/300 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 6000*1500 |

| Table Load Bearing (kg) | 3500 | |

| Overall Dimensions (mm) | Main Frame:8280*2900*2190 Tail Frame:6370*2260*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 1520 | |

| Y Axis Travel (mm) | 6050 | |

| Z Axis Travel (mm) | 140/300 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 4000*2000 |

| Table Load Bearing (kg) | 3500 | |

| Overall Dimensions (mm) | Main Frame:6300*3540*2190 Tail Frame:4380*2620*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2020 | |

| Y Axis Travel (mm) | 4050 | |

| Z Axis Travel (mm) | 140/300 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 6000*2000 |

| Table Load Bearing (kg) | 5000 | |

| Overall Dimensions (mm) | Main Frame:8280*3540*2190 Tail Frame:6370*2620*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2020 | |

| Y Axis Travel (mm) | 6050 | |

| Z Axis Travel (mm) | 140/300 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 6300*2200 |

| Table Load Bearing (kg) | 5500 | |

| Overall Dimensions (mm) | Main Frame:8850*3645*2320 Tail Frame:6660*2820*830 |

|

| Performance | Max. Acceleration | 1.5G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2220 | |

| Y Axis Travel (mm) | 6350 | |

| Z Axis Travel (mm) | 140/300 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 6300*2500 |

| Table Load Bearing (kg) | 12500 | |

| Overall Dimensions (mm) | Main Frame:8850*3870*2430 Tail Frame:6660*3100*980 |

|

| Performance | Max. Acceleration | 1.2G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2520 | |

| Y Axis Travel (mm) | 6350 | |

| Z Axis Travel (mm) | 150/350 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 8300*2500 |

| Table Load Bearing (kg) | 16500 | |

| Overall Dimensions (mm) | Main Frame:10850*3870*2430 Tail Frame:8660*3100*980 |

|

| Performance | Max. Acceleration | 1.2G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2520 | |

| Y Axis Travel (mm) | 8350 | |

| Z Axis Travel (mm) | 150/350 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

| Basic Parameters | Working Area (mm) | 13000*2500 |

| Table Load Bearing (kg) | 26000 | |

| Overall Dimensions (mm) | Main Frame:15850*3870*2430 Tail Frame:13660*3100*980 |

|

| Performance | Max. Acceleration | 1.2G |

| Max. Linkage Speed (m/min) | 120 | |

| Max Positioning Accuracy (m/min) | 100 | |

| X Axis Travel (mm) | 2520 | |

| Y Axis Travel (mm) | 13050 | |

| Z Axis Travel (mm) | 150/350 | |

| X,Y Axis Positioning Accuracy (mm/m) | ±0.02 | |

| X,Y Axis Repositioning Accuracy (mm/m) | ±0.02 |

Get in Touch with Us Now!

Please fill in the form and describe your requirements. Our team will get back to you within 24 hours.